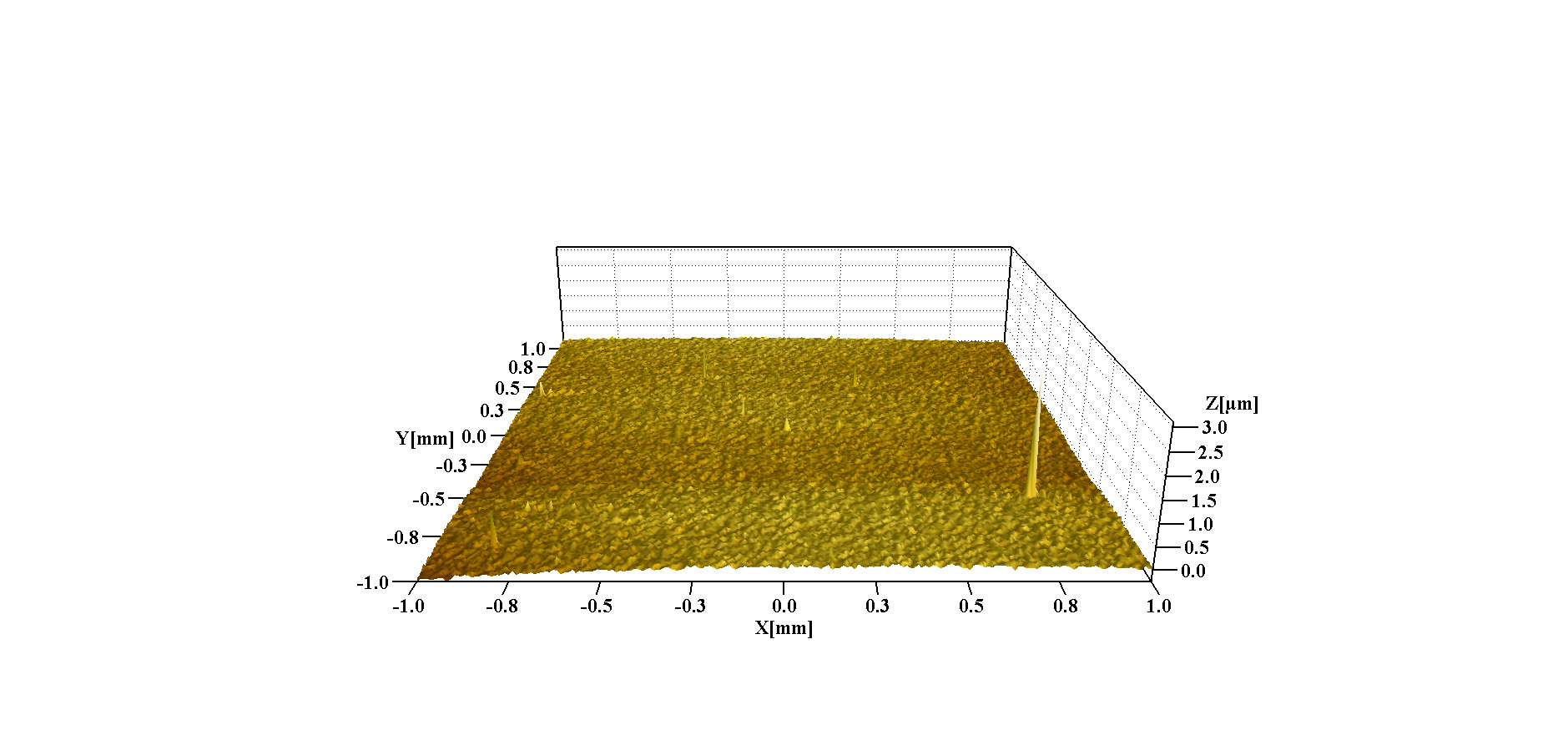

将烧结致密的(NbTaVWMo)C 块状样品粗磨-精磨后-粗抛后样品,采用粒度更小为1.0μm的金刚石研磨剂进行精抛10、20和30min三个时间段,使用NanoMap500DLS 型接触式轮廓仪通过Spip三维图像处理软件对粗磨后工件表面形貌数据采集,获取三维轮廓和表面粗糙度等信息;使用JSM-IT800型扫描电子显微镜对粗磨后工件表面形貌进行1000、5000和10000倍观察,扫描电压20 Kev,二次电子像。

The sintered dense (NbTaVWMo) C block sample was subjected to rough grinding, fine grinding, and rough polishing using a diamond abrasive with a particle size smaller than 1.0 μ m for three time periods of 10, 20, and 30 minutes. The NanoMap500DLS contact profilometer was used to collect surface morphology data of the workpiece after rough grinding using the Spip 3D image processing software, obtaining three-dimensional contour and surface roughness information; Use JSM-IT800 scanning electron microscope to observe the surface morphology of the workpiece after rough grinding at 1000, 5000, and 10000 times magnification, with a scanning voltage of 20 Kev and secondary electron images.