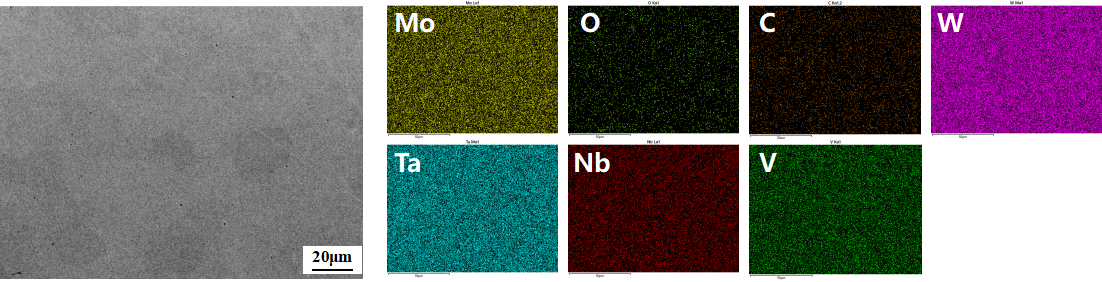

将烧结致密的(NbTaVWMo)C 块状样品粗磨-精磨后样品,在直径为250mm的金刚石磨抛盘进行粗抛,金刚石研磨剂为3.5μm,磨盘转速设为300转/min,载荷为55 N,用JSM-IT800型扫描电子显微镜对粗磨后工件表面形貌进行1000、5000和10000倍观察,扫描电压20 Kev,二次电子像。

The sintered dense (NbTaVWMo) C block sample was subjected to rough and fine grinding using a hot bending die. The sample was then subjected to rough grinding on a 250mm diameter diamond grinding disc with a diamond abrasive of 3.5 μ m, a grinding disc speed of 300 revolutions per minute, and a load of 55 N. The surface morphology of the workpiece after rough grinding was observed at 1000, 5000, and 10000 times using a JSM-IT800 scanning electron microscope with a scanning voltage of 20 Kev and a secondary electron image. Rough polishing EDS