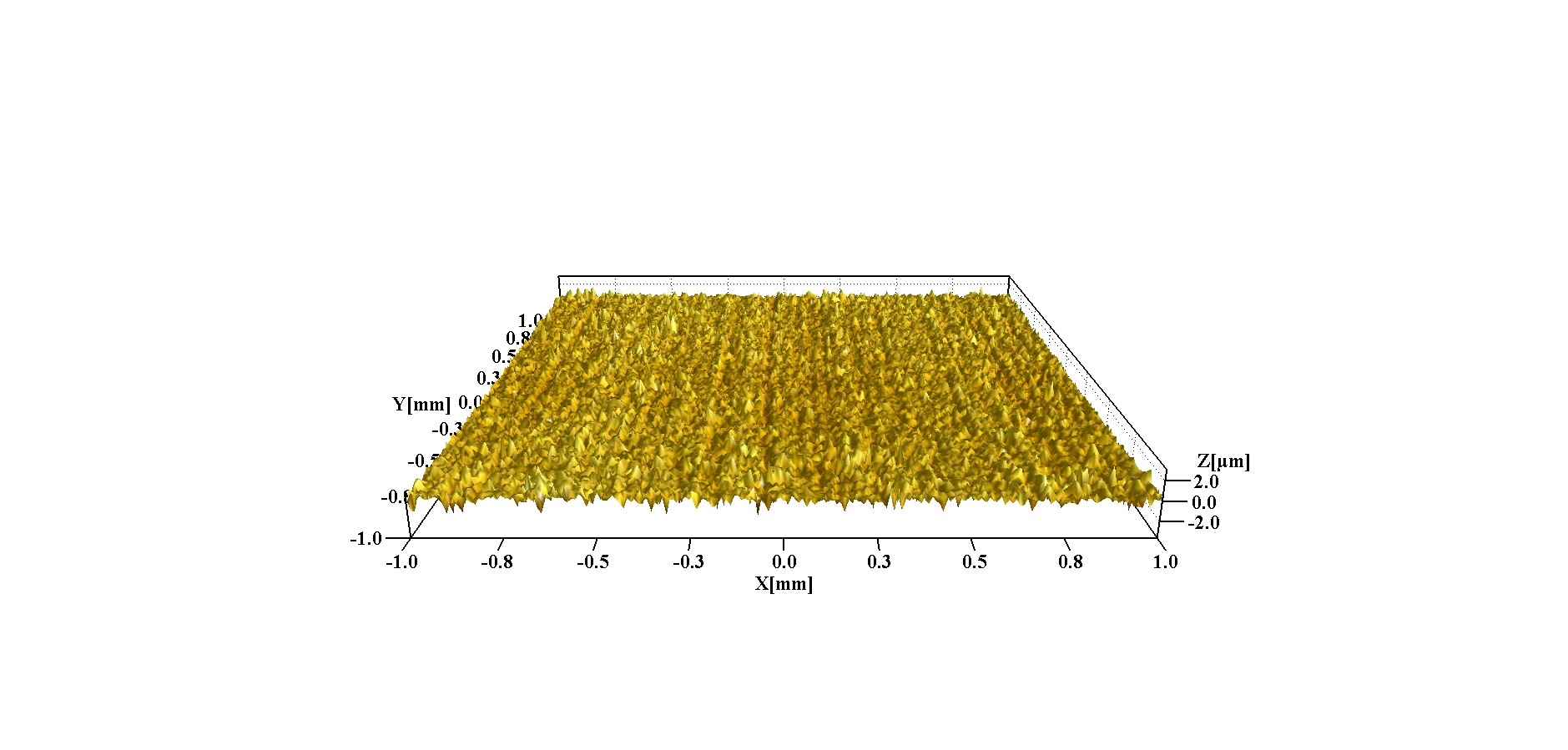

将烧结致密的(NbTaVWMo)C 块状样品,在尺寸为250*21*5mm的金刚石磨盘进行粗磨,粒度为220目,磨盘转速为300转/min, 载荷为60 N,使用NanoMap500DLS 型接触式轮廓仪通过Spip三维图像处理软件对粗磨后工件表面形貌数据采集,获取三维轮廓和表面粗糙度等信息

The sintered dense (NbTaVWMo) C block sample was roughly ground on a diamond grinding disc with a size of 250 * 21 * 5mm, a particle size of 220 mesh, a grinding disc speed of 300 revolutions per minute, and a load of 60 N. The NanoMap500DLS contact profilometer was used to collect surface morphology data of the workpiece after rough grinding using the Spip 3D image processing software, obtaining information such as 3D contour and surface roughness