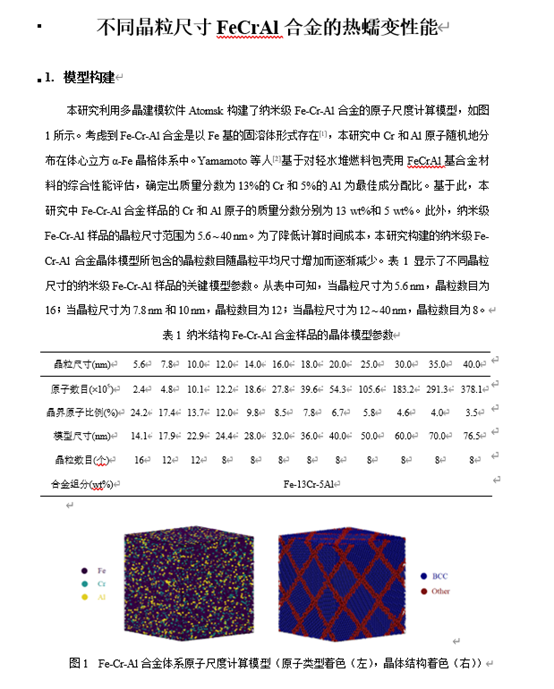

核燃料包壳作为反应堆的核心结构材料,在长期服役过程中会发生高温蠕变现象,导致材料机械性能降低,严重影响核能安全。因此探讨了晶粒尺寸变化对FeCrAl合金蠕变性能的影响规律。

As the core structural material of the reactor, the nuclear fuel cladding undergoes high-temperature creep during the long-term service process, resulting in a decrease in the mechanical properties of the material and seriously affecting the safety of nuclear energy. Therefore, the influence of grain size on creep properties of FeCrAl alloy is discussed.