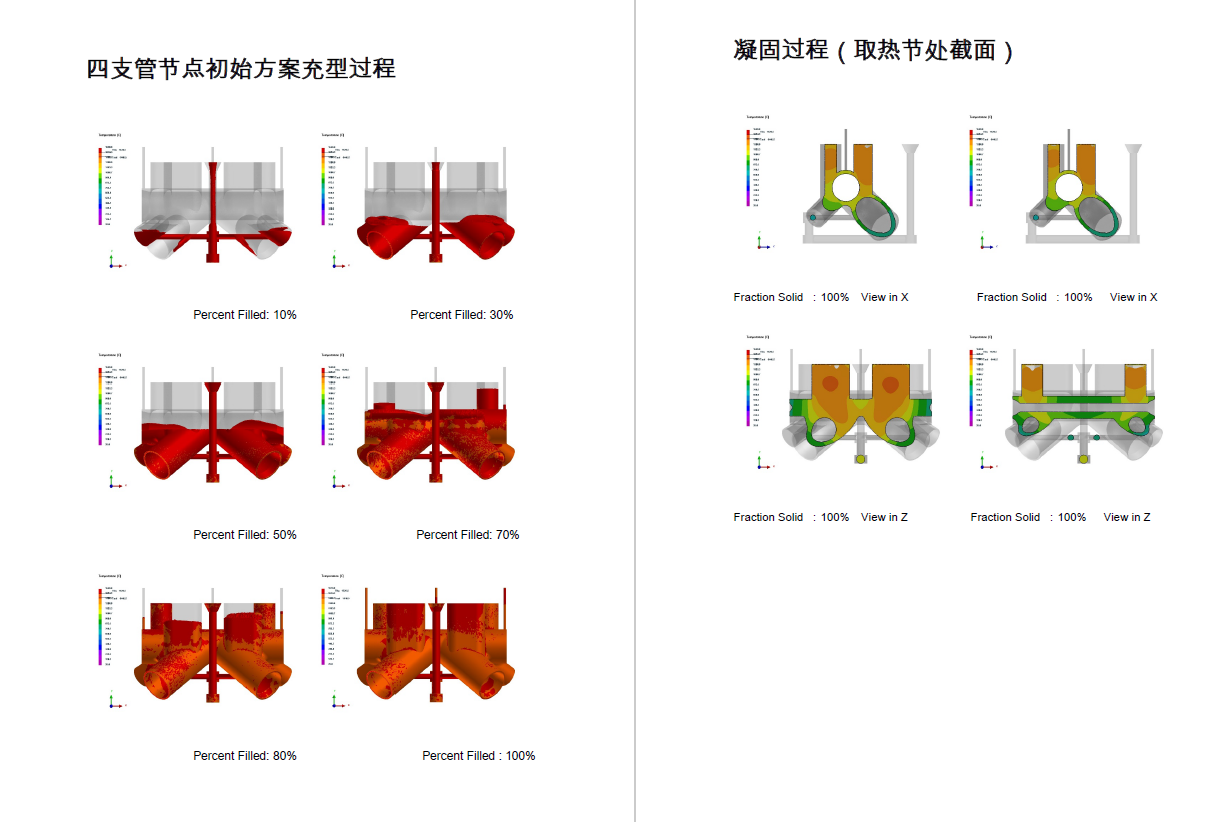

采用水平造型,水平浇注以及底注式浇注系统,在四个支管与主管连接热节处设置保温冒口,结果表明金属液充型平稳,但未达到顺序凝固,热节处易产生孔洞类缺陷。

Using horizontal molding, horizontal pouring and bottom injection pouring system, the heat preservation riser is set at the hot joint connecting four branch pipes and main pipe. The results show that the filling of liquid metal is stable, but it does not reach the sequence solidification, and holes are easy to occur at the hot joint.