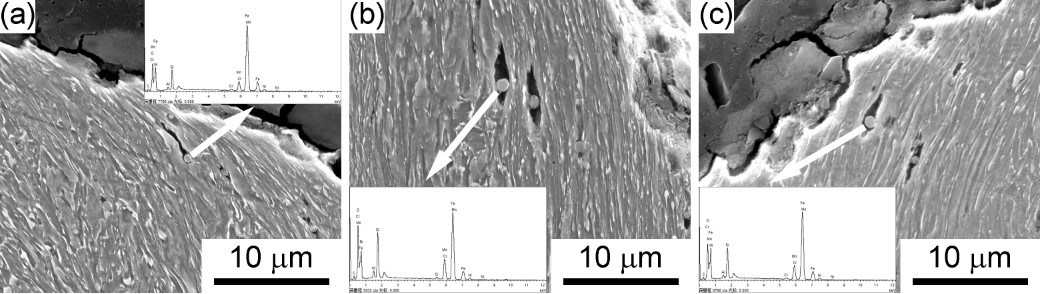

图(a)–(c)是不同V含量熔敷金属室温拉伸断口横截面形貌。可以看出,横截面上出现了明显塑性变形扭曲的痕迹,表明熔敷金属塑性较好。同时,在拉伸断口横截面上存在一些尺寸约为1 μm球状颗粒,能谱表明这些球状颗粒为Mn-Si-O的非金属夹杂物,由于拉伸过程中在它们与基体界面处发生应力集中,导致微裂纹主要以它们为核心产生,这些非金属夹杂物的存在恶化了熔敷金属的塑性。

Figures (a)-(c) are the cross-sectional morphologies of the tensile fracture surfaces of the deposited metals with different V contents at room temperature. It can be seen that there are obvious plastic deformation and distortion marks on the cross section, indicating that the deposited metal had better plasticity. At the same time, there were some spherical particles with a size of about 1 μm in the cross section of the tensile fracture. The energy spectrum showed that these spherical particles were non-metallic inclusions of Mn-Si-O. Because the stress concentration was occurred at the interface between them and the matrix during the stretching process, which caused micro-cracks to occur mainly with them as the core. The existence of these non-metallic inclusions deteriorated the plasticity of the deposited metal.