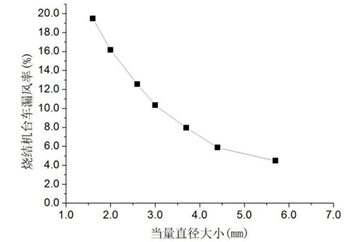

如上图中曲线关系可得,漏风率随当量直径增大而减小。颗粒当量直径从1.6mm增至5.7mm时,烧结机台车漏风率从19.457%降至4.465%,且烧结机台车漏风率减少量随物料当量直径增大而减小。烧结料当量直径大小会对烧结料层的气体动力学状况以及化学反应产生很大影响,烧结料当量直径过低将无法使烧结料层充分烧结,烧结料粒度过高,对应的比表面积将减少,不利于还原。故在烧结工艺领域,料层颗粒当量直径的主要生产变化范围为2.0~5.0mm。在混合物料当量直径2.0~5.0mm的生产变化范围内,物料粒度4.4mm时漏风率最低。

As shown in the curve relationship in the above figure, the air leakage rate decreases as the equivalent diameter increases. When the particle equivalent diameter increases from 1.6mm to 5.7mm, the air leakage rate of the sintering machine trolley decreases from 19.457% to 4.465%, and the reduction of the air leakage rate of the sintering machine trolley decreases as the material equivalent diameter increases. The equivalent diameter of the sinter material will have a great influence on the gas dynamics and chemical reaction of the sinter material layer. If the equivalent diameter of the sinter material is too low, the sinter material layer will not be fully sintered. If the particle size of the sinter material is too high, the corresponding specific surface area will be reduced. , Is not conducive to reduction. Therefore, in the field of sintering process, the main production variation range of the equivalent diameter of the material layer particle is 2.0-5.0mm. Within the production variation range of the mixed material equivalent diameter of 2.0~5.0mm, the air leakage rate is the lowest when the material particle size is 4.4mm.