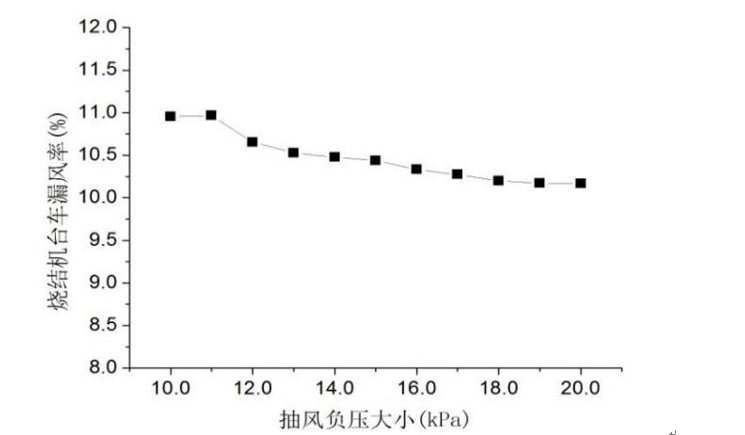

如上图中曲线关系可得,抽风机负压对烧结机漏风影响不太显著,随着抽风机负压的增大,烧结机台车漏风率呈现减小趋势。当抽风负压大于18000Pa时候,漏风率变化量几乎可以忽略不计。考虑到低的抽风负压会降低烧结生产率,过高的抽风负压将加快燃烧速度,导致烧结矿强度降低,烧结矿质量无法满足烧结工艺要求,故在整个烧结领域抽风负压生产变化范围取12000Pa~18000Pa。

As shown in the curve relationship in the above figure, the negative pressure of the exhaust fan does not have a significant impact on the air leakage of the sintering machine. As the negative pressure of the exhaust fan increases, the air leakage rate of the sintering machine trolley shows a decreasing trend. When the suction pressure is greater than 18000Pa, the change in air leakage rate is almost negligible. Taking into account that low suction negative pressure will reduce the sintering productivity, too high suction negative pressure will speed up the burning speed, resulting in a decrease in the strength of the sinter, and the quality of the sinter cannot meet the requirements of the sintering process. Therefore, the range of ventilation and negative pressure production changes in the entire sintering field is taken 12000Pa~18000Pa.