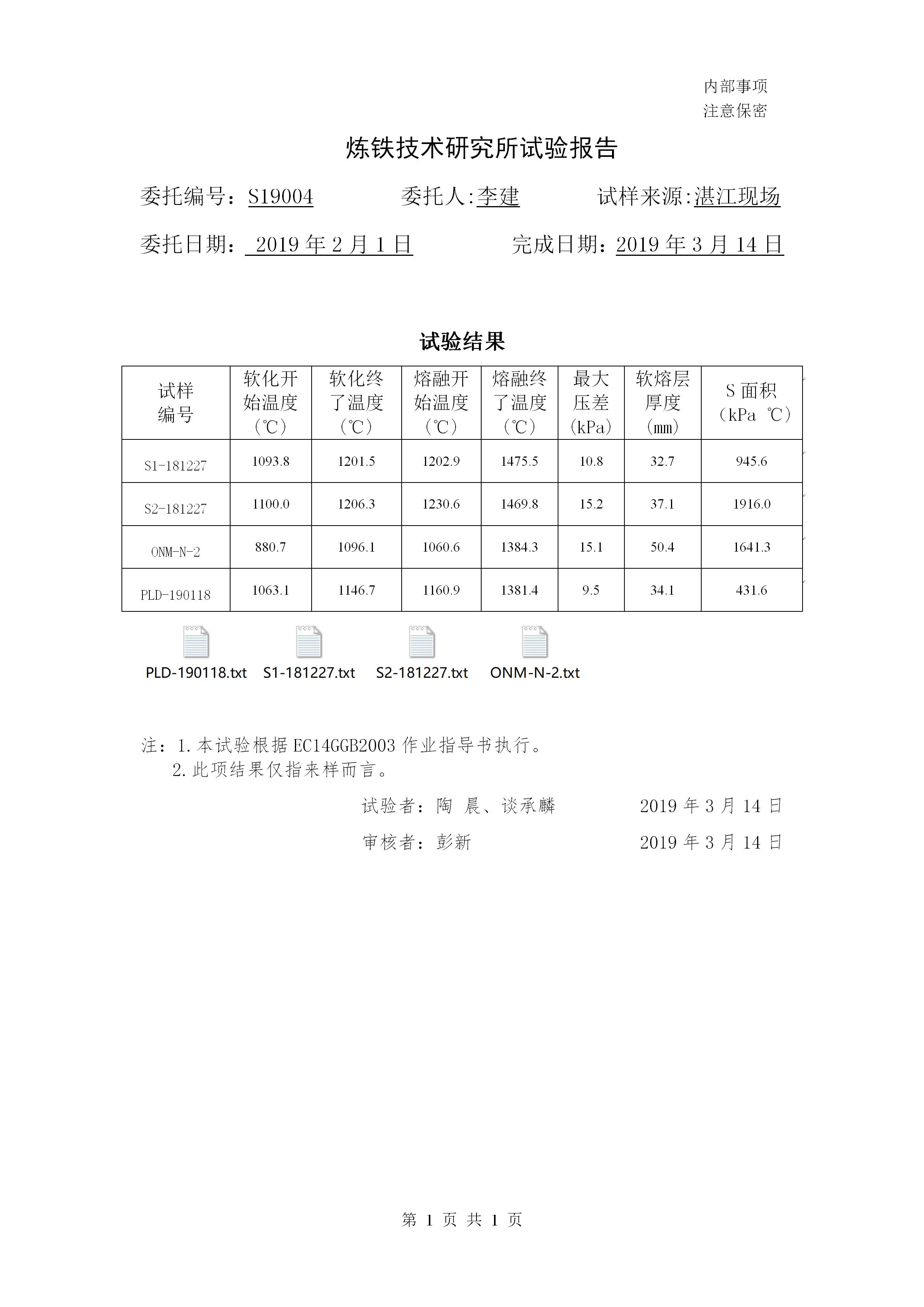

2018年底,湛江一座高炉炉况波动增加,另一座高炉较稳定,对应的2台烧结机生产的烧结矿进行了熔滴性能分析,同时,对块矿和自熔性球团进行了分析。结果表明,2DL烧结机生产的烧结矿压差较大,S面积院大于1DL生产的烧结矿。不同炉料对比表明,自熔性球团S面积最小,纽曼块矿次之,烧结矿最大。但块矿存在软化温度偏低的不足。结果表明,在配矿结构相同,烧结矿成分相似的条件下,烧结操作参数的差异也会造成烧结矿熔滴性能存在较大的差异。实验结果为改善烧结、高炉操作提供了参考数据。

At the end of 2018, the furnace condition fluctuation of one blast furnace in Zhanjiang increased and the other blast furnace was relatively stable. The droplet performance analysis was carried out on the sinter produced by the corresponding two sintering machines. At the same time, the lump ore and self fusible pellets were analyzed. The results show that the pressure difference of sinter produced by 2DL sintering machine is large, and the s area is larger than that produced by 1dl sintering machine. The comparison of different charges shows that the s area of self fluxing pellets is the smallest, Newman lump ore is the second, and sinter is the largest. However, the softening temperature of lump ore is low. The results show that under the conditions of the same ore blending structure and similar sinter composition, the difference of sintering operation parameters will also lead to great differences in the droplet properties of sinter. The experimental results provide reference data for improving sintering and blast furnace operation.