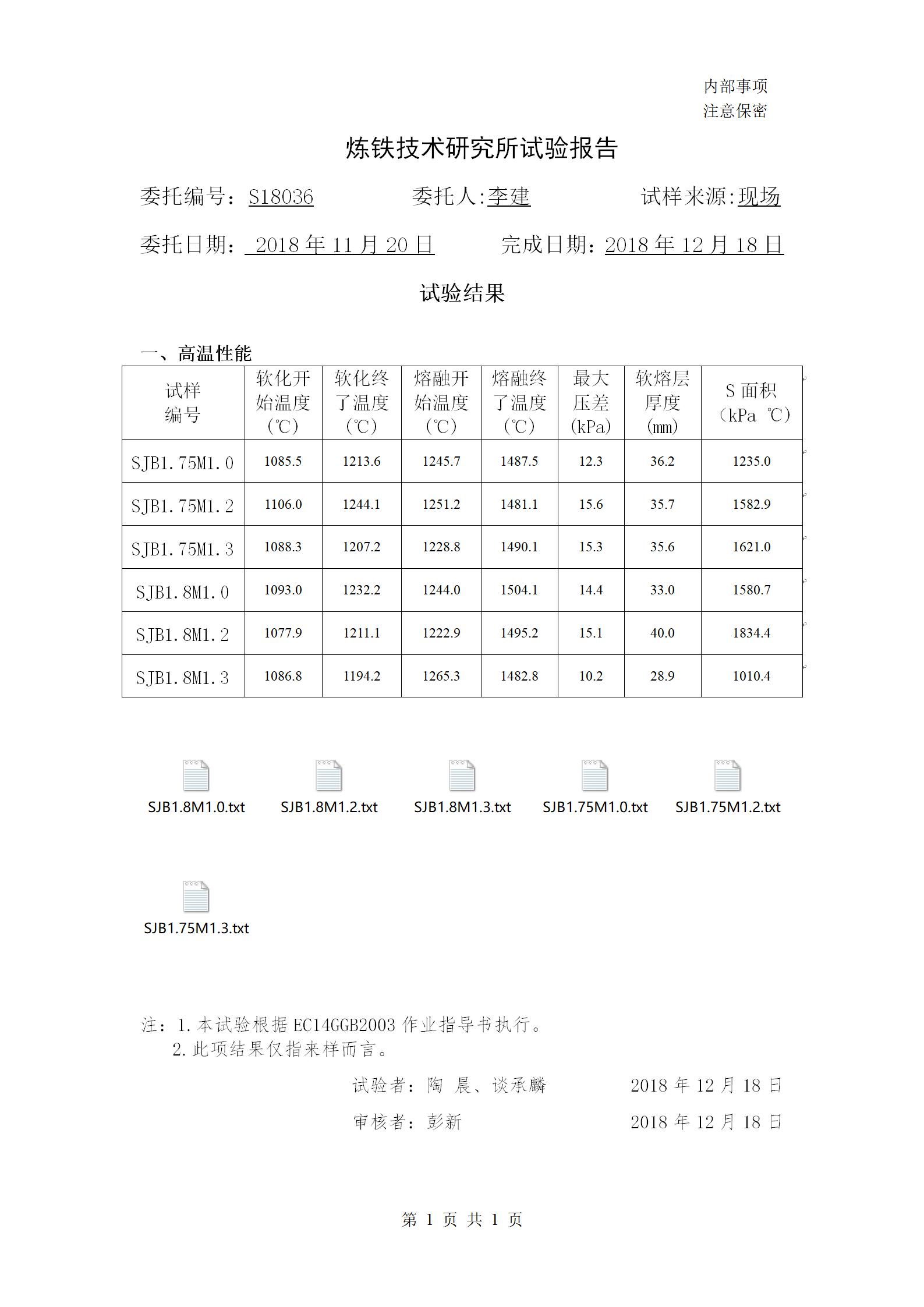

对碱度1.75,1.80两个水平,氧化镁含量1.0-1.3%三个水平的烧结矿进行了熔滴性能检测,结果表明,随着碱度升高,烧结矿软化温度升高,但S面积也同步升高。在碱度1.75的条件下,随着MgO含量的提高,S面积从1235.0 kPa.℃提高至1621.0 kPa.℃,在碱度1.8的条件下,也呈现类似的规律。结果表明,若烧结矿的碱度和MgO含量同步升高,由于碱性化合物的熔点更高,将会造成烧结矿熔滴性能变差,有可能对高炉炉况带来不利影响。

The droplet properties of sinter with alkalinity of 1.75 and 1.80 and magnesium oxide content of 1.0-1.3% were tested. The results show that with the increase of alkalinity, the softening temperature of sinter increases, but the s area also increases synchronously. Under the condition of alkalinity 1.75, with the increase of MgO content, the s area increases from 1235.0 kPa. ℃ to 1621.0 kPa. ℃. Under the condition of alkalinity 1.8, it also shows a similar law. The results show that if the basicity and MgO content of sinter increase simultaneously, the higher melting point of alkaline compounds will lead to the poor droplet performance of sinter, which may have an adverse impact on the condition of blast furnace.