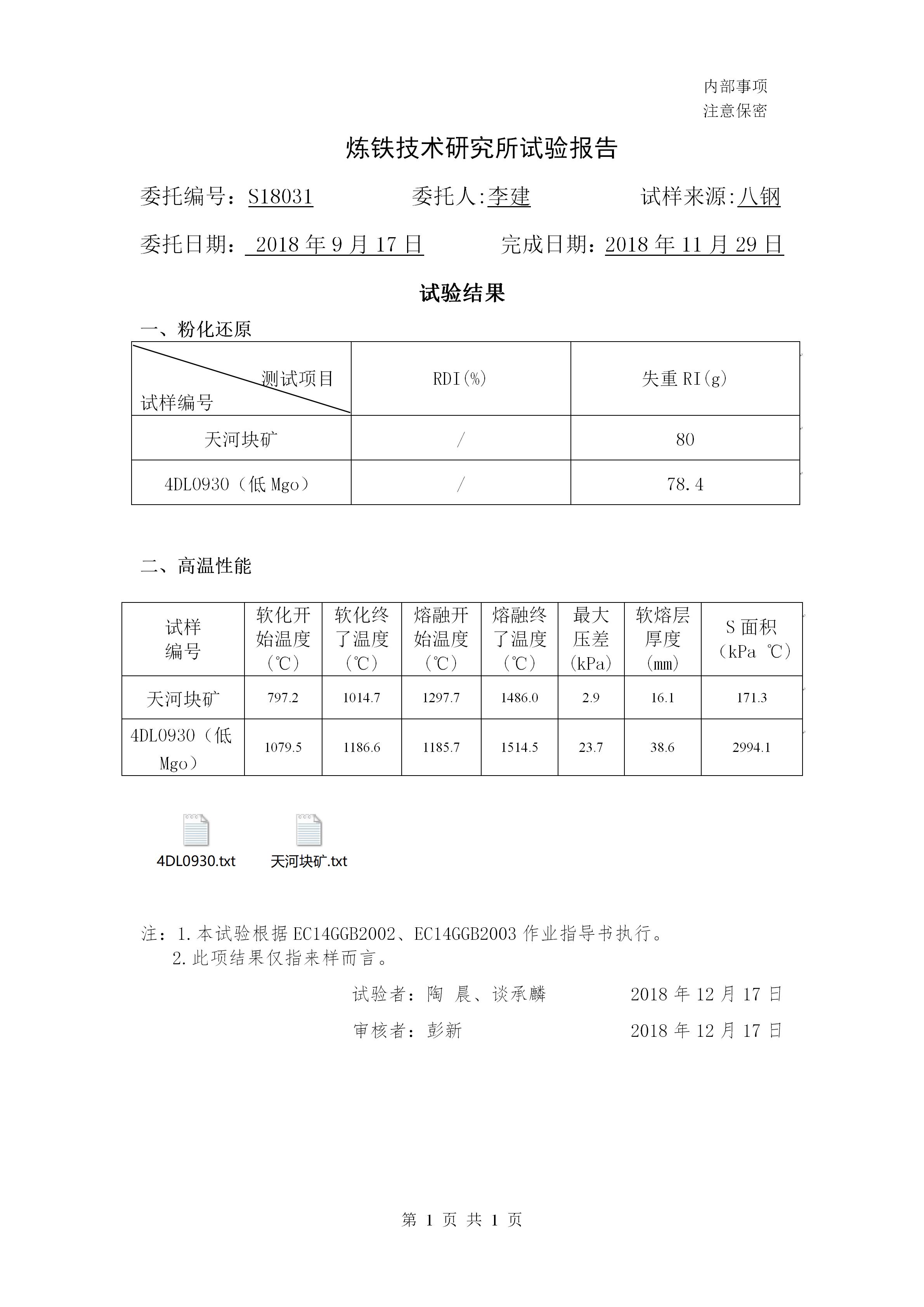

2018年9月,为配合高炉使用高镁熔剂性球团,烧结生产了MgO含量为1.2%的低镁烧结矿,其熔滴性能与以往有所不同。同时,对中国宝武某公司拟高炉拟使用的高硅块矿进行了熔滴性能分析,该块矿硅含量达到15%左右。测试结果表明,低镁烧结矿S面积比同碱度高镁烧结矿小,有利于降低高炉压差。同时高硅块矿虽然S面积较小,但存在软化开始温度低的不足,判断其可用于高炉生产,且对软熔带透气性影响较小,但因软化温度偏低,使用比例不宜太高,需控制在<5%。

In September 2018, in order to cooperate with the blast furnace to use high magnesium flux pellets, low magnesium sinter with MgO content of 1.2% was produced by sintering, and its droplet performance is different from that in the past. At the same time, the droplet properties of the high silicon lump ore to be used in the blast furnace of a company in Baowu, China are analyzed. The silicon content of the lump ore is about 15%. The test results show that the s area of low magnesium sinter is smaller than that of high magnesium sinter with the same basicity, which is conducive to reducing the pressure difference of blast furnace. At the same time, although the s area of high silicon lump ore is small, it has the disadvantage of low softening starting temperature. It is judged that it can be used in blast furnace production and has little impact on the permeability of soft melt zone. However, due to the low softening temperature, the use proportion should not be too high and should be controlled at < 5%.