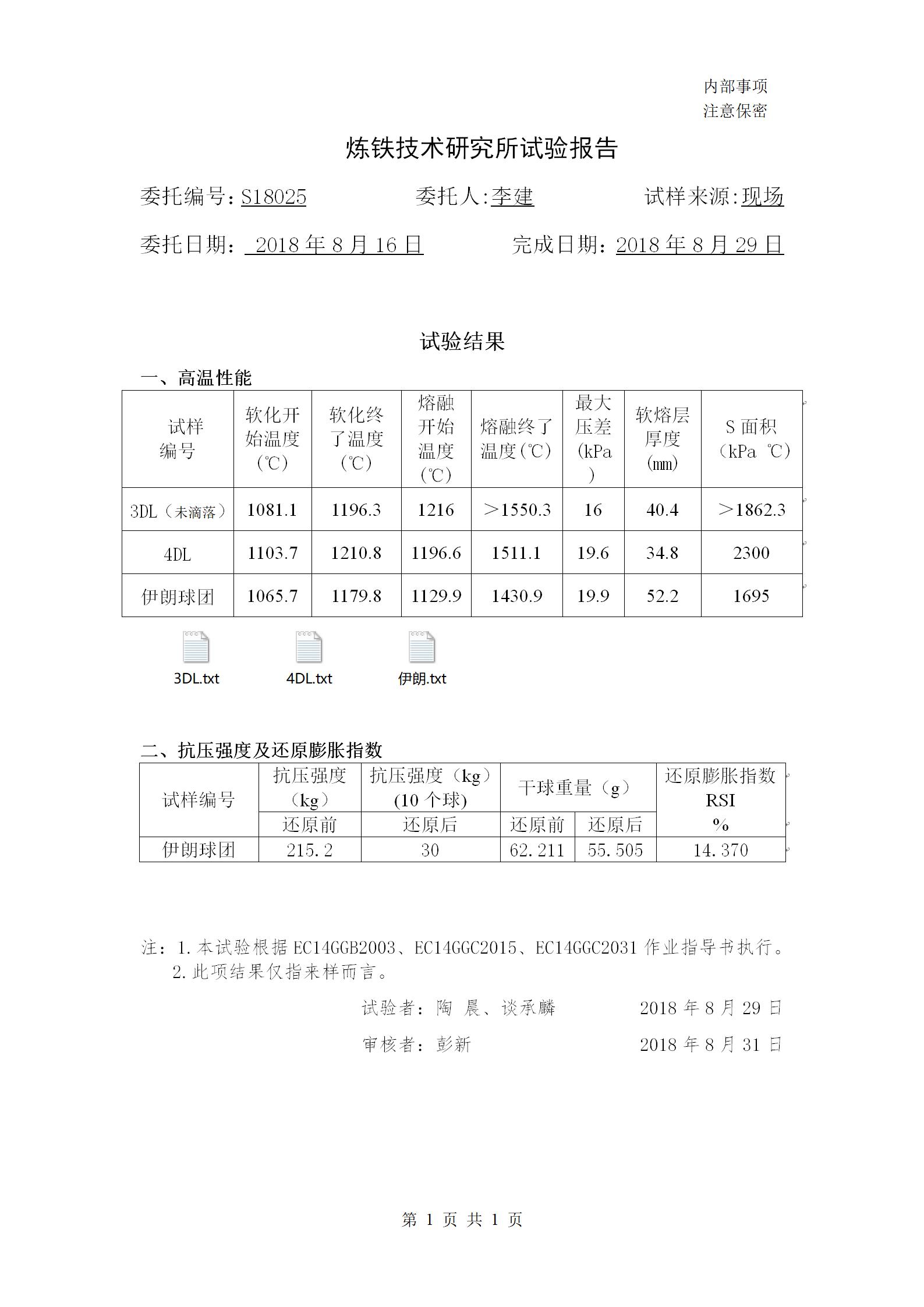

2018年8月,对2台烧结机生产的高碱度烧结与伊朗球团熔滴性能进行了对比,结果表明,烧结矿具有软化温度高、熔点高的特点,其软熔层厚度分别为40.4,34.8mm,而伊朗球团软化温度较低,软熔层厚度达到52.2mm。但球团的S面积比烧结矿小,表明在高炉冶炼过程中,使用一定比例不会对炉况造成显著的影响。

In August 2018, the high basicity sintering produced by two sintering machines was compared with the droplet properties of Iranian pellets. The results show that the sinter has the characteristics of high softening temperature and high melting point. The thickness of soft melt layer is 40.4 and 34.8mm respectively, while the softening temperature of Iranian pellets is low, and the thickness of soft melt layer is 52.2mm. However, the s area of pellets is smaller than that of sinter, which shows that the use of a certain proportion will not have a significant impact on the furnace condition in the process of blast furnace smelting.