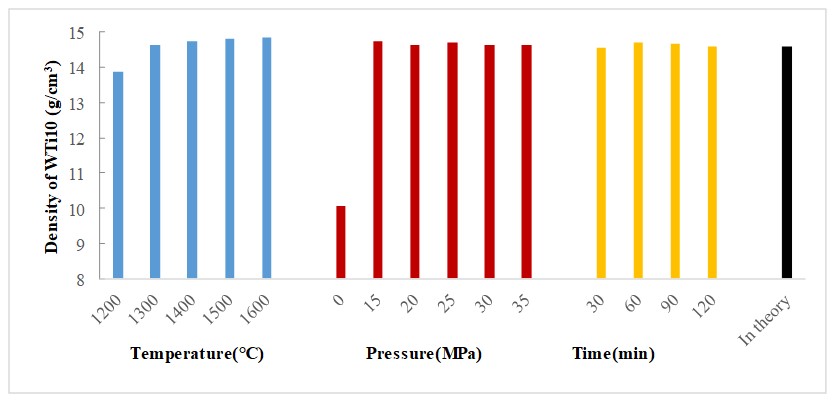

采用高温高压工艺制备了WTi10合金。使用电子探针、扫描电子显微镜及X射线衍射仪等手段研究制备工艺对合金密度及微观组织的影响,尤其是合金中的相演变特征。评价靶材对合金相的要求,并据此获取优化的制备工艺。

The WTi10 alloy was prepared by the high temperature and high pressure process. Use electron probe, scanning electron microscope and X-ray diffractometer to study the influence of the preparation process on the alloy density and microstructure, especially the phase evolution characteristics in the alloy. Evaluate the requirements of the target for the alloy phase, and obtain the optimized preparation process accordingly.