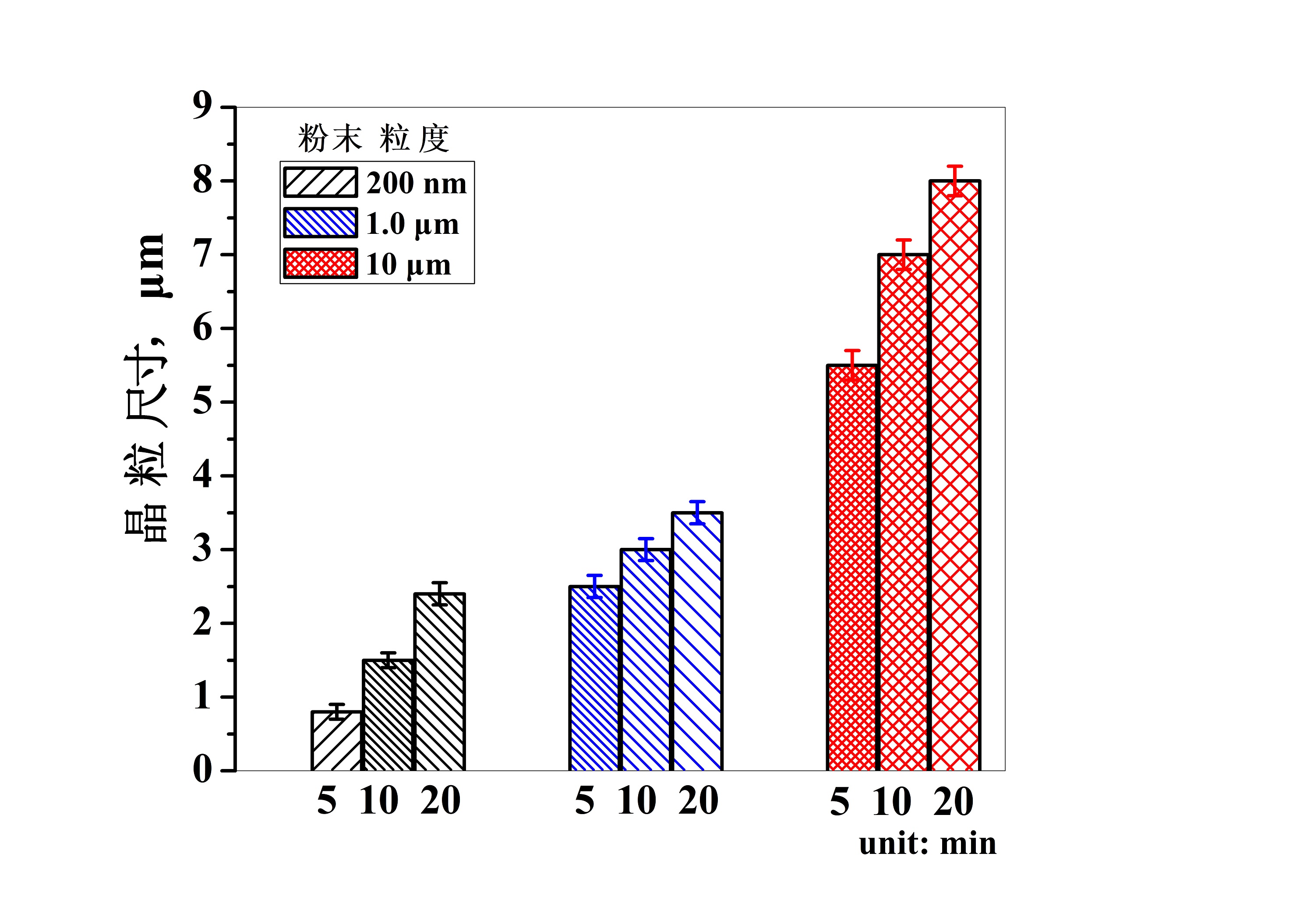

使用200nm、1μm、2μm和10μm等粒度的高纯钨粉末,借助放电等离子烧结(SPS)炉进行快速高温压力烧结,制备出尺寸为φ60×10 mm的样品。烧结气氛为真空,烧结压力50MPa,烧结温度为1350-1500℃,保温时间为10分钟。借助扫描电镜观察人为折断样品断口处的晶粒形貌,并拍摄SEM照片;在图像处理软件Image J 中统计出SEM照片中烧结纯钨的平均晶粒尺寸。借助Origin绘图软件,绘制出不同烧结条件纯钨样品的平均晶粒尺寸分布曲线。

High-purity tungsten powders with particle sizes of 200nm, 1μm, 2μm and 10μm were used for rapid high-temperature pressure sintering with a spark plasma sintering (SPS) furnace to prepare samples with a size of φ60×10 mm. The sintering atmosphere is vacuum, the sintering pressure is 50MPa, the sintering temperature is 1350-1500°C, and the holding time is 10 minutes. Observe the morphology of the crystal grains at the fracture of the artificially broken sample with the help of scanning electron microscope, and take SEM pictures; in the image processing software Image J, calculate the average crystal grain size of sintered pure tungsten in the SEM pictures. With the aid of Origin drawing software, the average grain size distribution curves of pure tungsten samples under different sintering conditions are drawn.