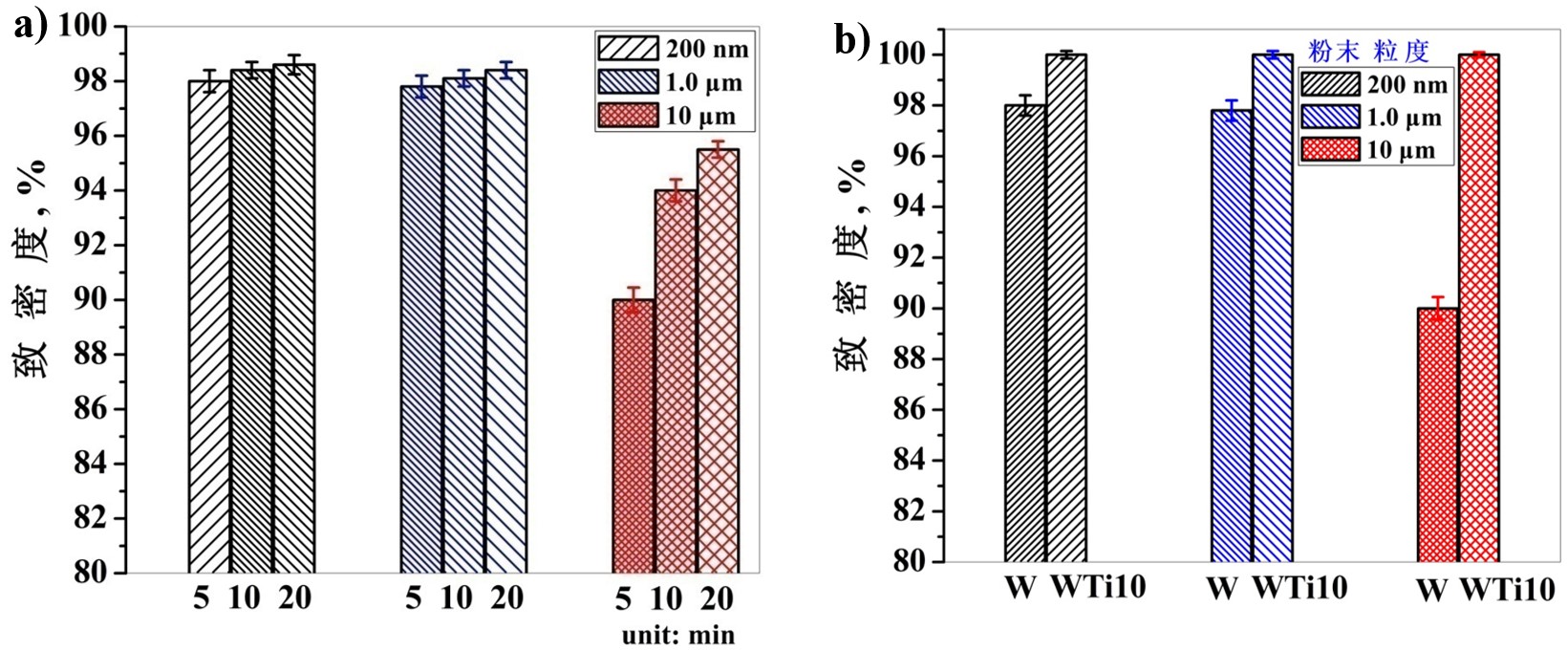

使用200nm、1μm、2μm和10μm等粒度的高纯钨粉末,借助放电等离子烧结(SPS炉)进行快速的高温压力烧结,制备出尺寸为φ60 × 10mm的样品。烧结气氛为真空,烧结压力50MPa,烧结温度为1350-1500℃,保温时间为10分钟。借助阿基米德排水法测试样品的烧结密度,然后用烧结密度除以理论密度,获得烧结纯钨样品的相对密度值。使用Origin软件绘制出纯钨样品的相对密度变化曲线,反映初始粉末粒度和烧结条件对纯钨致密度的影响。

Using high-purity tungsten powder with particle sizes of 200nm, 1μm, 2μm and 10μm, rapid high-temperature pressure sintering by spark plasma sintering (SPS furnace) was used to prepare samples with a size of φ60 × 10mm. The sintering atmosphere is vacuum, the sintering pressure is 50MPa, the sintering temperature is 1350-1500°C, and the holding time is 10 minutes. The sintered density of the sample was tested by the Archimedes drainage method, and then the sintered density was divided by the theoretical density to obtain the relative density value of the sintered pure tungsten sample. Use Origin software to draw the relative density change curve of pure tungsten sample, reflecting the influence of initial powder particle size and sintering conditions on the density of pure tungsten.