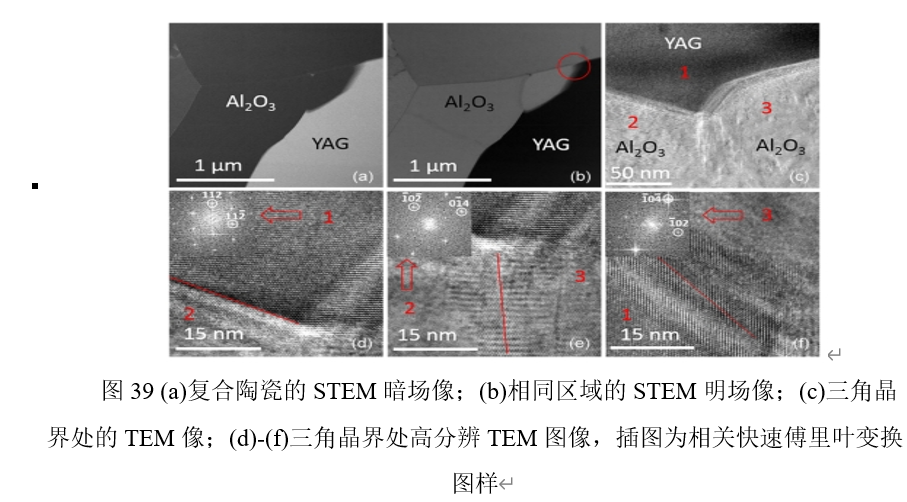

相比较于单相陶瓷的晶界界面,复合陶瓷的晶界界面由于两相的晶体结构和化学本质的不同,会存在更大的热阻。为了研究Al2O3和YAG:Ce3+颗粒之间的晶界界面,我们利用STEM和高分辨TEM技术进行分析,如图39所示。根据Y和Al元素的原子序数、Z衬度的不同,首先通过STEM明场像和暗场像来区分Al2O3和YAG颗粒,YAG:Ce3+颗粒的明场像较暗,暗场像较亮;Al2O3颗粒与其恰好相反。在此基础上研究了YAG:Ce3+和Al2O3颗粒之间的三角晶界。不难发现,无论是Al2O3和YAG:Ce3+之间,还是Al2O3和Al2O3之间,晶界都紧密连接、且清晰干净,利于热量的传导。此外,各个晶粒的高分辨TEM图像以及相关的快速傅里叶变换图样均证实颗粒具有良好的结晶性。

Compared with the grain boundary interface of single-phase ceramics, the grain boundary interface of composite ceramics will have greater thermal resistance due to the different crystal structure and chemical essence of the two phases. In order to study the grain boundary interface between Al2O3 and YAG: Ce3 + particles, we analyzed it by stem and high-resolution TEM, as shown in Fig. 39. According to the atomic number and Z contrast of Y and Al elements, Al2O3 and YAG particles are distinguished by stem bright field image and dark field image. The bright field image of YAG: Ce3 + particles is darker and the dark field image is brighter; Al2O3 particles are just the opposite. On this basis, the triangular grain boundary between YAG: Ce3 + and Al2O3 particles was studied. It is not difficult to find that the grain boundaries are closely connected and clear between Al2O3 and YAG: Ce3 +, or between Al2O3 and Al2O3, which is conducive to heat conduction. In addition, the high-resolution TEM images and related fast Fourier transform patterns of each grain confirm that the particles have good crystallinity.