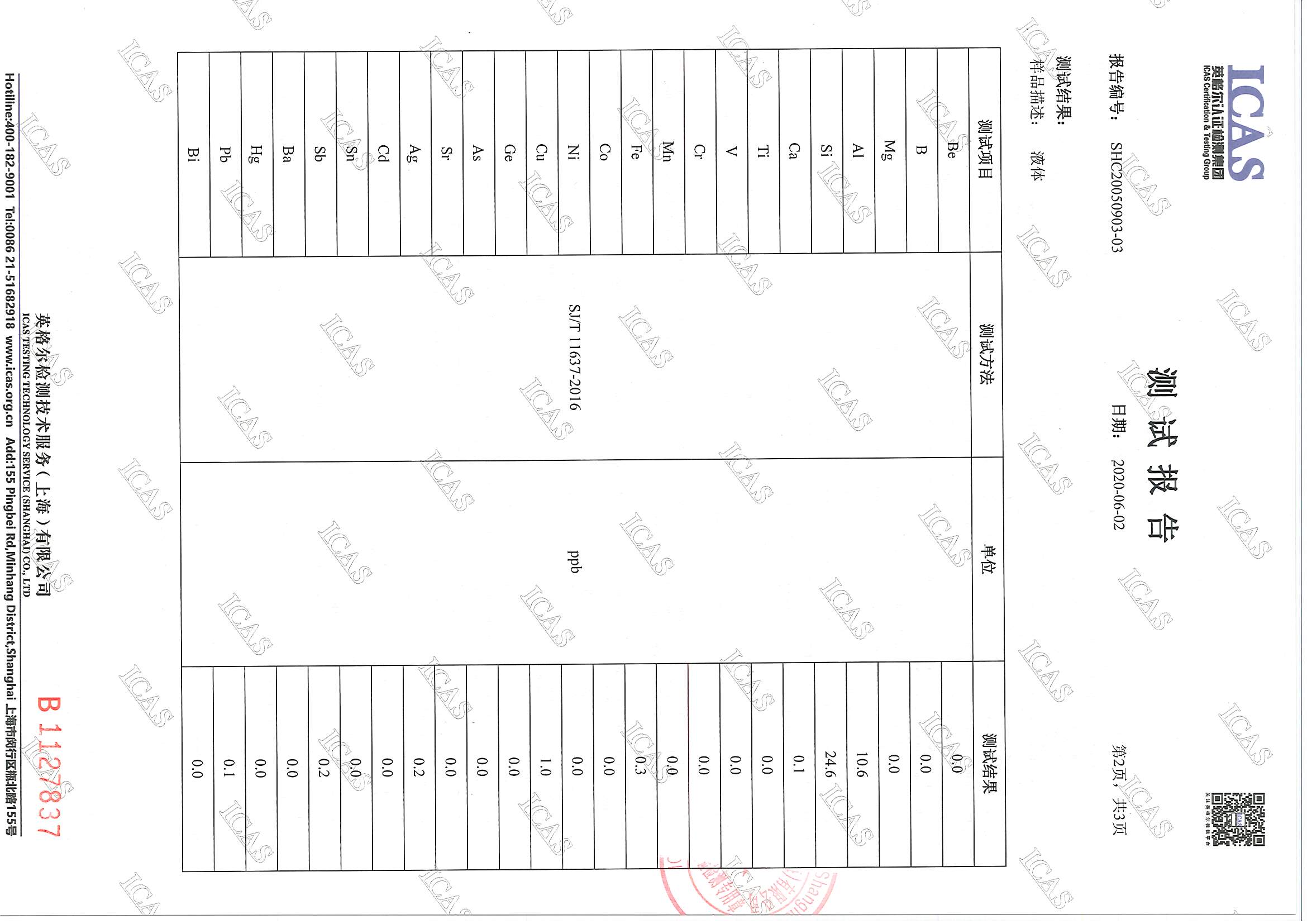

超高纯二甲基锌(纯度大于7N)中杂质如有机硅化合物、烷基铝氧化物等,其含量约为几个ppm级,甚至是ppb级,这种ppb级含量的杂质难以用常规分析仪器检测。ICP-MS进行无机杂质的检测,方法简单,对不同元素的测定。具有检出限极低ppb级、重现性好,一次分析多种元素等显著特点。二甲基锌样品处理过程:先氧化,再用酸溶解成水溶液,稀释后进行测试,使用ICP-MS仪器进行分析,测量方法参照《电子化学品 电感耦合等离子体质谱法通则》来确保检测纯度的可靠性。针对二甲基锌下游产品处延片及最终的光电器件或高频器件质量产生影响,从而确定了需检测的杂质。最终依据这五种(硅、铜、镁、铝和铁)有害元素含量(相对于基体锌的重量百分比的总量),差量法来判定出二甲基锌的纯度。

Ultra-high purity dimethyl zinc (purity greater than 7N) impurities such as organosilicon compounds, alkyl aluminum oxides, its content is about several ppm level, or even ppb level, this ppb level of impurities is difficult to detect with conventional analytical instruments. ICP-MS for the detection of inorganic impurities, the method is simple, the determination of different elements. The detection limit is very low ppb, reproducibility is good, and multiple elements are analyzed at one time.Dimethyl zinc sample processing process: first oxidized, then dissolved into an aqueous solution with acid, diluted after testing, using ICP-MS instrument for analysis, measurement method according to "Electronic chemicals inductively coupled plasma mass spectrometry" to ensure the reliability of purity detection. The impurities to be detected were determined in view of the influence on the quality of the wafer and the final photoelectric devices or high-frequency devices in the downstream products of dimethyl zinc. Finally, the purity of dimethyl zinc was determined by the difference method according to the contents of five harmful elements (silicon, copper, magnesium, aluminum and iron) relative to the total weight percentage of zinc matrix.