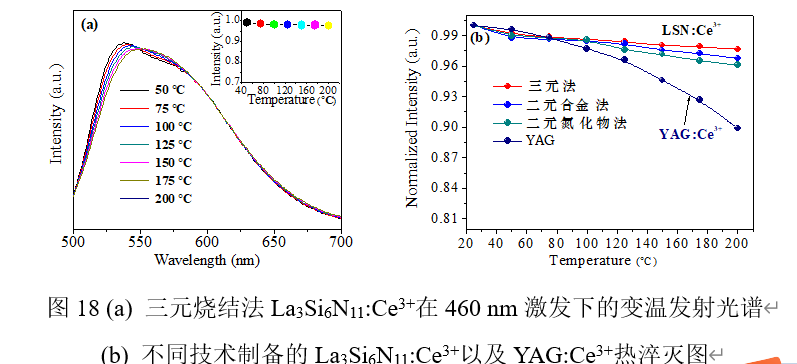

课题组研究了三种方法制备的LSN:Ce的热稳定性,即其在460 nm激发下的变温光谱特性,如图18所示。由图可知,当温度由50℃升高至200℃时,采用可控三元烧结技术制备的LSN:Ce黄粉发射强度基本保持不变,右上角插图显示,发光强度下降不到2%,热稳定性明显优于二元氮化物法和二元合金法,二元氮化物法和二元合金法在高温下LSN:Ce衰减明显,说明利用三元可控技术制备的LSN:Ce黄粉粉是一款温度特性极好的实用性荧光粉,热稳定性优异,特别适合高能量激发用LED照明领域。

The research group studied the thermal stability of LSN: CE prepared by three methods, that is, its variable temperature spectral characteristics under 460 nm excitation, as shown in Fig. 18. It can be seen from the figure that when the temperature increases from 50 ℃ to 200 ℃, the emission intensity of LSN: CE yellow powder prepared by controllable ternary sintering technology basically remains unchanged. The illustration in the upper right corner shows that the luminous intensity decreases by less than 2%, and the thermal stability is obviously better than that of binary nitride method and binary alloy method. The LSN: CE attenuation of binary nitride method and binary alloy method is obvious at high temperature, It shows that LSN: CE yellow powder prepared by ternary controllable technology is a practical phosphor with excellent temperature characteristics and excellent thermal stability, especially suitable for LED lighting field for high-energy excitation.