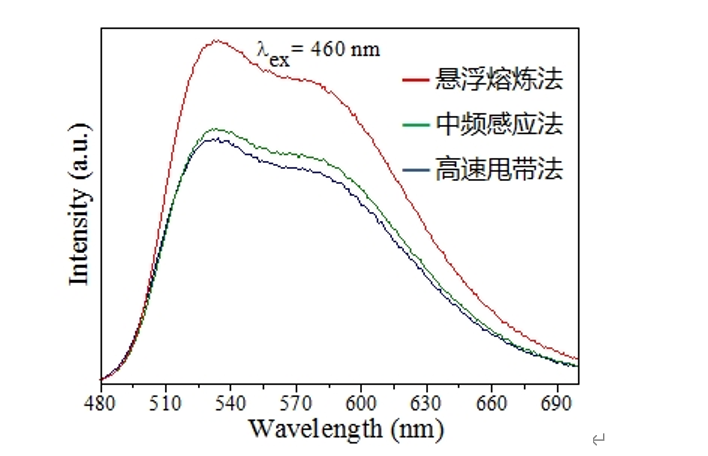

LSN:Ce结构黄粉制备无论采用LaN+Si3N4二元氮化物烧结法还是LaSi合金+Si3N4二元合金法,高纯原料LaSi合金和LaN均是制备该类高性能荧光粉的关键核心因素,但市场没有成熟产品。基于此,课题组开发了LSN:Ce结构黄粉用高纯原料制备技术。课题组通过深入研究熔炼方式对合金组织结构及硬度和最终荧光粉性能的影响,优选出合金悬浮熔炼制备技术,制得组织结构均一的高纯LaSi合金。不同熔炼方式所制备的合金XRD和块体组织结构,如图1所示。中频感应法和高速甩带法制备的合金易出现LaSi2异相引起成分偏析,且致密性强、硬度高、粉碎困难,致使LSN:Ce结构黄粉原料混合不均匀,易生成La1Si3N5及氮氧化物杂相,严重影响荧光粉最终光色性能,而悬浮熔炼所得的等轴晶合金不仅相纯度高,而且质地疏松、破碎容易,可制备高纯LSN:Ce结构黄粉。

Preparation of LSN: CE structure yellow powder whether LAN + Si3N4 binary nitride sintering method or Lasi alloy + Si3N4 binary alloy method is adopted, high-purity raw materials Lasi alloy and LAN are the key core factors for preparing this kind of high-performance phosphor, but there is no mature product in the market. Based on this, the research group developed the preparation technology of high-purity raw materials for LSN: CE yellow powder. Through in-depth study of the effects of melting methods on the alloy microstructure, hardness and final phosphor properties, the research group optimized the alloy suspension melting preparation technology to prepare high-purity Lasi alloy with uniform microstructure. XRD and block microstructure of alloys prepared by different melting methods are shown in Fig. 1. The alloys prepared by medium frequency induction method and high-speed strip throwing method are prone to LaSi2 heterogeneous phase, resulting in composition segregation, strong compactness, high hardness and difficult crushing, resulting in uneven mixing of LSN: CE yellow powder raw materials, easy to generate La1Si3N5 and nitrogen oxide heterophases, which seriously affect the final photochromic properties of phosphors. The equiaxed alloy obtained by suspension melting not only has high phase purity, but also has loose texture It is easy to break and can prepare high-purity LSN: CE yellow powder.