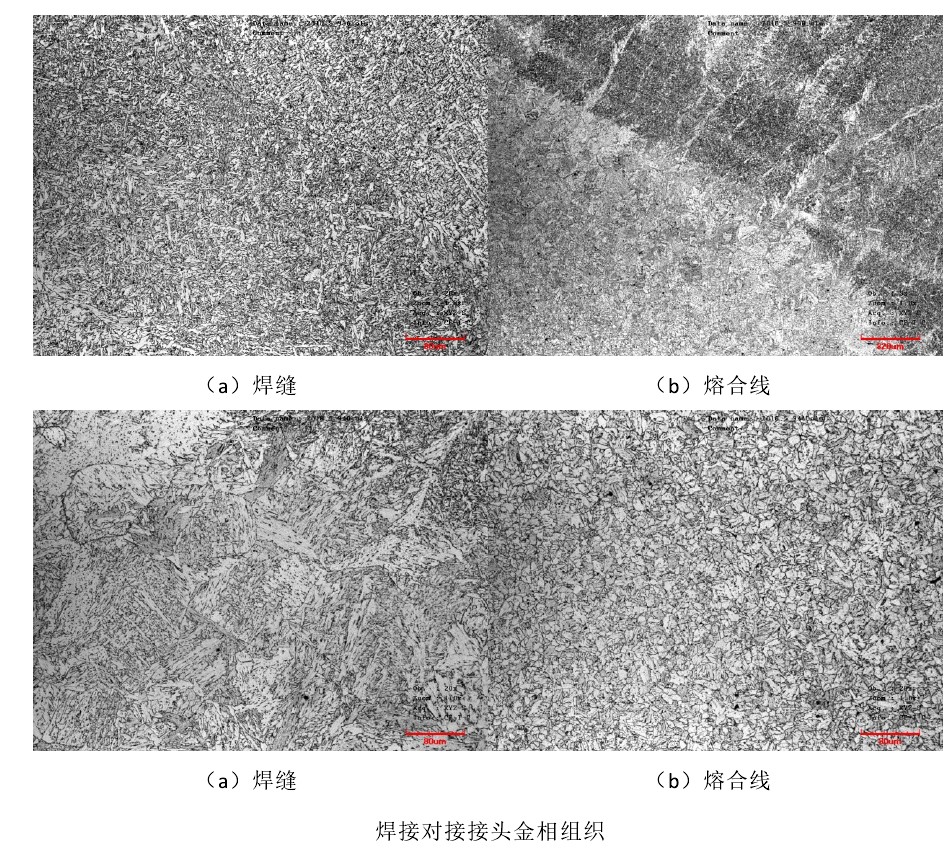

本研究中,我们采用所开发的焊材与对应钢板进行对接接头焊接试验,焊接坡口为单面60°坡口,采用电焊条打底+埋弧焊填充盖面工艺进行焊接,焊前焊后不预热,焊接热输入控制为25KJ/cm。该数据为对接接头的金相组织。

In this study, the butt joint welding test was carried out by using the developed welding material and the corresponding steel plate. The welding groove was a single-sided 60° groove, and the welding process was conducted by using the electrode backing + submerged arc welding filling cover. There was no preheating before and after welding, and the welding heat input was controlled at 25KJ/cm. The data is the metallographic structure of the butt joint.