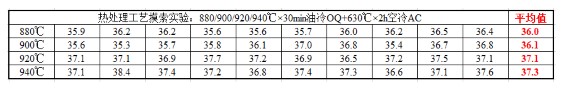

自主设计Cr-Ni-Cu-Ti-V-Nb合金成分体系,C0.23,Si 0.20,Mn0.68,P0.006,S0.003,Cr0.97,Ni0.38,Cu0.35,Mo0.53,V0.093,Ti0.048,Nb0.034,Al0.027.在上述成分基础上,优化设计热处理工艺制度,880℃、900℃、920℃和940℃下保温30min,630℃回火实验,获得耐火螺栓钢不同淬火温度下硬度分析。硬度值在36-37.3HRC。

The independent design of Cr-Ni-Cu-Ti-V-Nb alloy composition system, C0.23, Si 0.20, Mn0.68, P0.006, S0.003, Cr0.97, Ni0.38, Cu0.35, Mo0.53, V0.093, Ti0.048, Nb0.034, Al0.027. On the basis of the above components, the heat treatment process was optimized. The heat treatment process was optimized at 880℃, 900℃, 920℃ and 940℃ for 30min, and the tempering experiment was conducted at 630℃. The hardness analysis of fireproof bolt steel at different quenching temperatures was obtained. Hardness value is 36-37.3HRC.