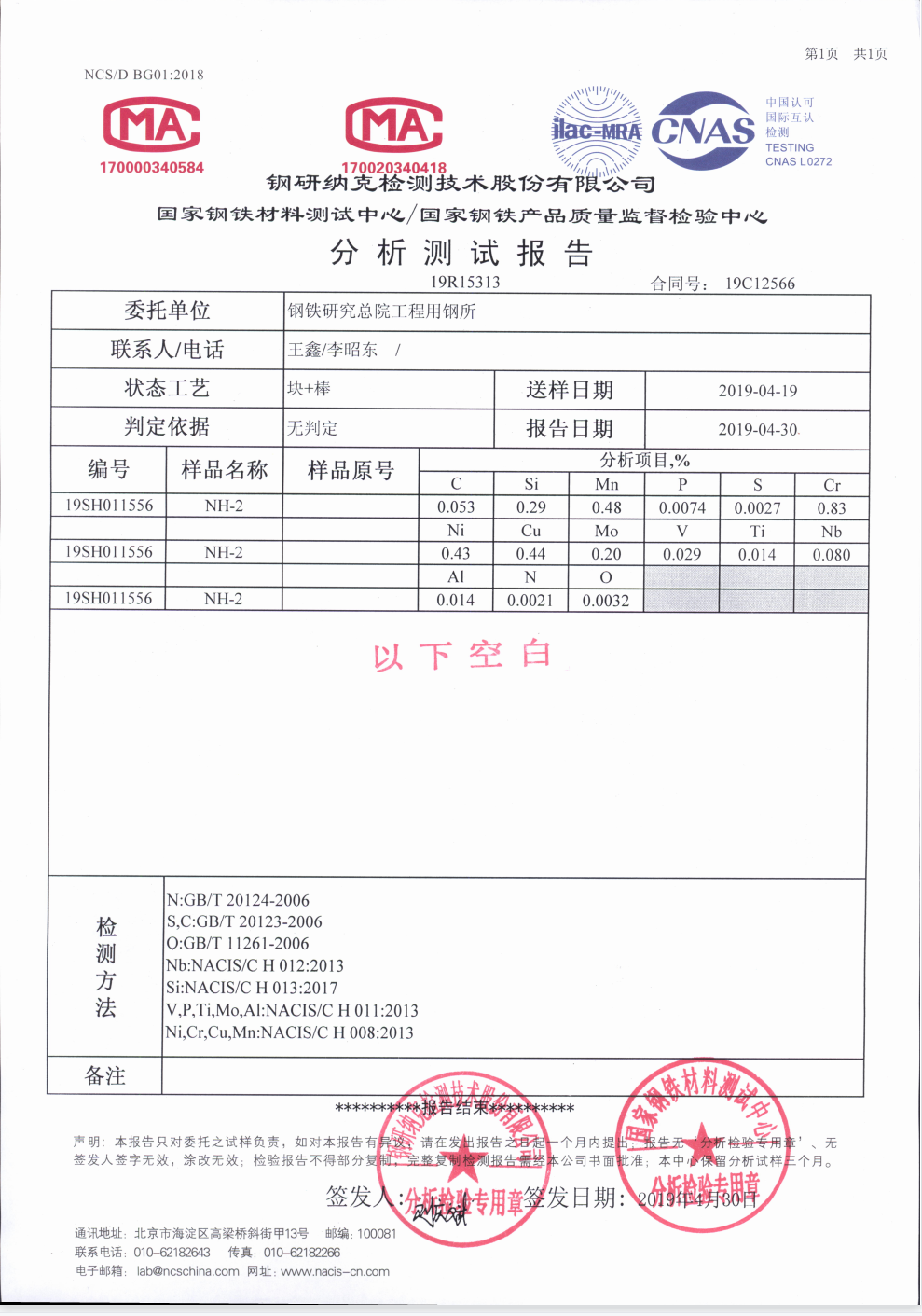

本研究采用低碳设计,提高钢材的焊接性能;锰是提高淬透性元素,且成本低廉,能在一定范围内同时提高强韧性;铬能同时提高钢材的强度、耐火性能和耐蚀性能;镍能降低了位错运动的阻力,使应力松弛,提高钢的塑韧性;钼能显著提高钢的耐火性能和耐大气腐蚀性能。铌、钒和钛协同析出细小的碳氮化物,钉扎界面、位错等缺陷,提高高温强度。

This study adopts low-carbon design to improve the welding performance of steel; Manganese is an element that improves hardenability with low cost and can improve strength and toughness within a certain range. Chromium can simultaneously improve the strength, fire resistance and corrosion resistance of steel. Nickel can reduce the resistance of dislocation movement, relax the stress and improve the plasticity and toughness of steel. Molybdenum can significantly improve the fire resistance and atmospheric corrosion resistance of steel. Niobium, vanadium and titanium cooperate to precipitate fine carbonitrides, nail the interface, dislocation and other defects, improve the high temperature strength.