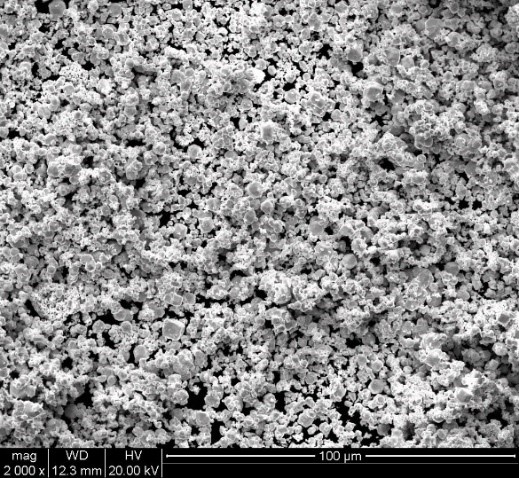

大尺寸高相对密度钨管制品对于石英熔炼行业具有重要的应用价值,为了克服大尺寸钨管在制备过程中易出现压坯开裂和相对密度不高的问题,对不同粒度钨粉进行了掺混实验,研究了混合时间对压坯强度的影响。研究表明,对掺混钨粉进行气流破碎处理,可以有效地缩小粒度分布范围,提高颗粒均匀性。通过对压制压强和保压时间的研究,发现压制压强>230 MPa 时,延长保压时间或提高压制压强并不会提高压坯强度。通过慢速升温烧结实验,发现钨管收缩率较大的温度集中在1600 ℃ 以下,延长中低温烧结时间可以较好的提高钨管的相对密度。

Tungsten tube products with large size and high relative density are of great application value in quartz smelting industry.in order to overcome the problems of cracking and low relative density of tungsten tube products with large size, mixing experiments of tungsten powder with different particle sizes were carried out to study the influence of mixing time on the strength of tungsten tube products. The results show that airflow crushing can effectively reduce the particle size distribution and improve particle uniformity. Through the study of pressure and holding time, it is found that pressure > At 230 MPa, prolonging the holding time or increasing the pressing pressure will not improve the strength of the blank. Through slow sintering experiments, it is found that the temperature of tungsten tube shrinkage is concentrated below 1600 ℃, and the relative density of tungsten tube can be improved by prolongating the sintering time of medium and low temperature.