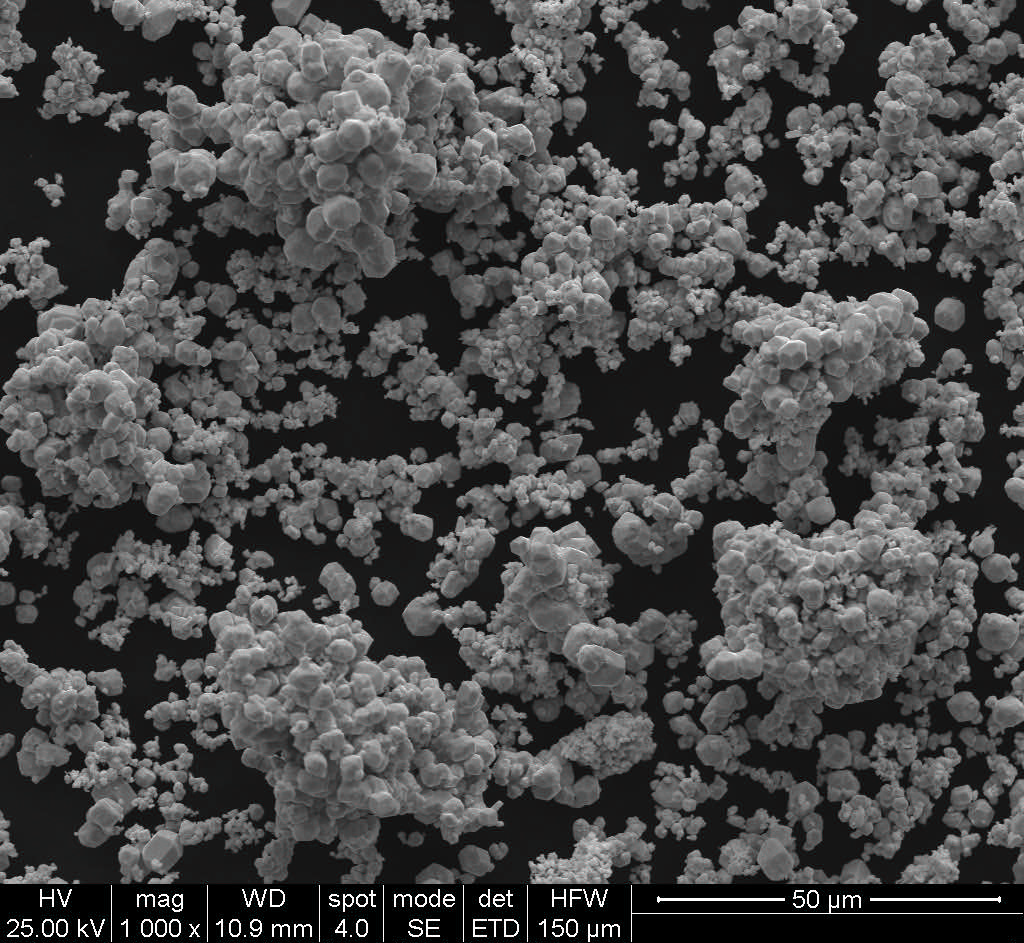

为解决钨粉团聚及粒度控制对后续制品的影响,研究了机械打散、机械研磨、气流分级和射流分级四种分散分级方式,分析了不同钨粉产物的SEM形貌与粒度分布。结果表明采用射流分级技术实现了钨粉精确分级,分级后中粉产物粒径收窄明显。该技术对于致密材料的制备提供了可控技术手段。

In order to solve the influence of tungsten powder agglomeration and particle size control on subsequent products, four dispersion classification methods, mechanical dispersing, mechanical grinding, air classification and jet classification were studied, and the SEM morphology and particle size distribution of different tungsten powder products were analyzed. The results show that the precise classification of tungsten powder is achieved by the jet classification technology, and the particle size of the intermediate powder product is significantly narrowed after classification. This technology provides a controllable technical means for the preparation of dense materials.