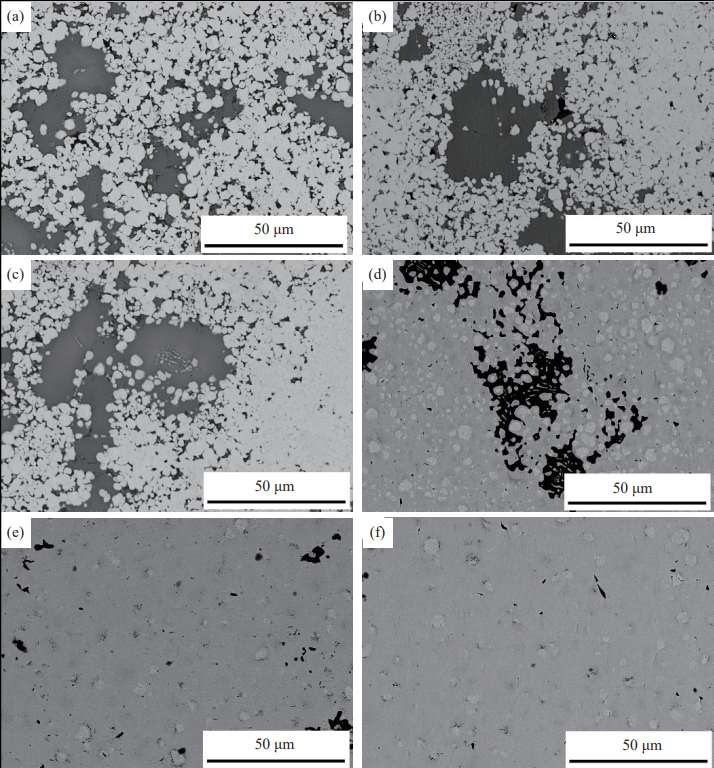

在已有WTi10热压靶材制备工艺条件下,通过增加后续退火工艺,改善材料的组织结构,提高材料的纯度.采用基恩士体式显微镜,扫描电子显微镜和辉光放电质谱仪等设备观察和测量材料的显微组织,晶粒尺寸和纯度.结果表明,随着退火温度的升高,富钛β1(W,Ti)相逐渐减少,富钨β(W,Ti)相逐渐增多;当退火温度低于1200℃时,材料的主要组织为W相,富钨β(W,Ti)相和富钛β1(W,Ti)相;当退火温度达到1700℃时,富钛β1(W,Ti)相基本消失,形成平均晶粒尺寸为7.9μm的均匀再结晶组织,其O质量分数仅为0.041%,而纯度达到99.995%以上。

The microstructure and purity of WTi10 hot-pressed target material were improved by adding subsequent annealing process. The microstructures, grain size and purity of the materials were observed and measured by Means of Gene type microscope, scanning electron microscope and glow discharge mass spectrometer. The results show that ti-rich β1(W,Ti) phase decreases and w-rich β(W,Ti) phase increases with increasing annealing temperature. When the annealing temperature is lower than 1200℃, the main microstructure of the material is W phase, w-rich β(W,Ti) phase and Ti-rich β1(W,Ti) phase. When the annealing temperature reaches 1700℃, the ti-rich β1(W,Ti) phase almost disappears, forming a uniform recrystallized microstructure with an average grain size of 7.9μm. The O mass fraction of β1(W,Ti) is only 0.041%, and the purity is more than 99.995%.