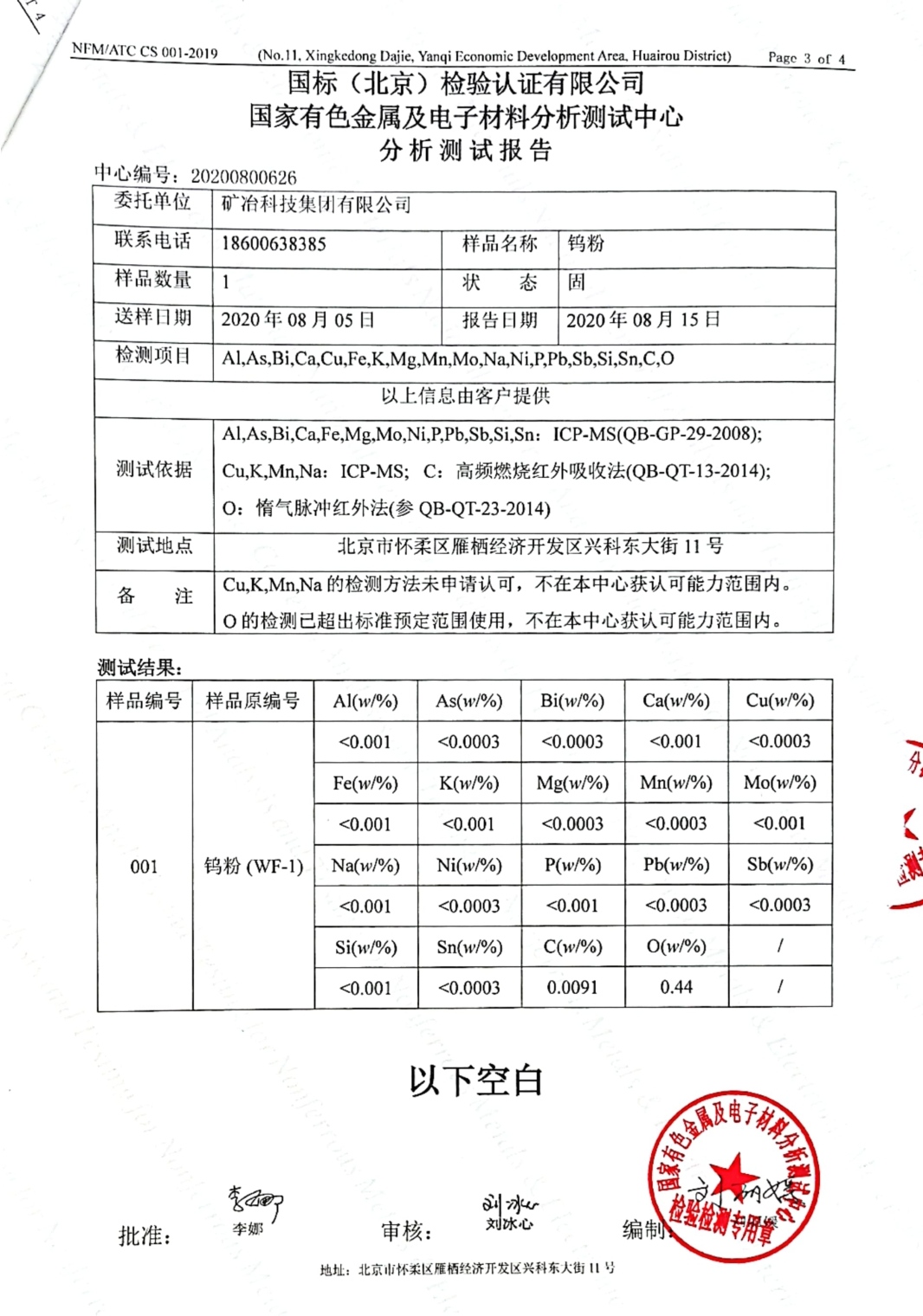

在制备硬质合金的过程中,可能会引入各种杂质,其对性能产生的影响也各有差异。可以对钨产生影响的杂质种类较多,含量较多的杂质元素会通过形成固溶体、化合物或者与其他杂质元素产生交互作用,而对钨制品性能有显著的影响。杂质含量、存在形式、引入阶段都各有不同,对钨制品性能的影响也各有差异,因此需要研究适当的加工工艺,以提高钨制品纯度。项目组对原料粉末进行二次还原,并进行压坯和烧结。取不同阶段的样品进行GDMS测试。结果表明,烧结具有明显的除杂作用,可显著降低钨制品内部杂质含量。

In the process of preparing cemented carbide, various impurities may be introduced, and their effects on performance are also different. There are many types of impurities that can affect tungsten, and the more content of impurity elements will have a significant impact on the performance of tungsten products by forming solid solutions, compounds or interacting with other impurity elements. The impurity content, existence form, and introduction stage are all different, and the influence on the performance of tungsten products is also different. Therefore, it is necessary to study the appropriate processing technology to improve the purity of tungsten products. The project team performed a secondary reduction of the raw material powder, and performed compaction and sintering. Take samples at different stages for GDMS testing. The results show that sintering has an obvious impurity removal effect and can significantly reduce the internal impurity content of tungsten products.