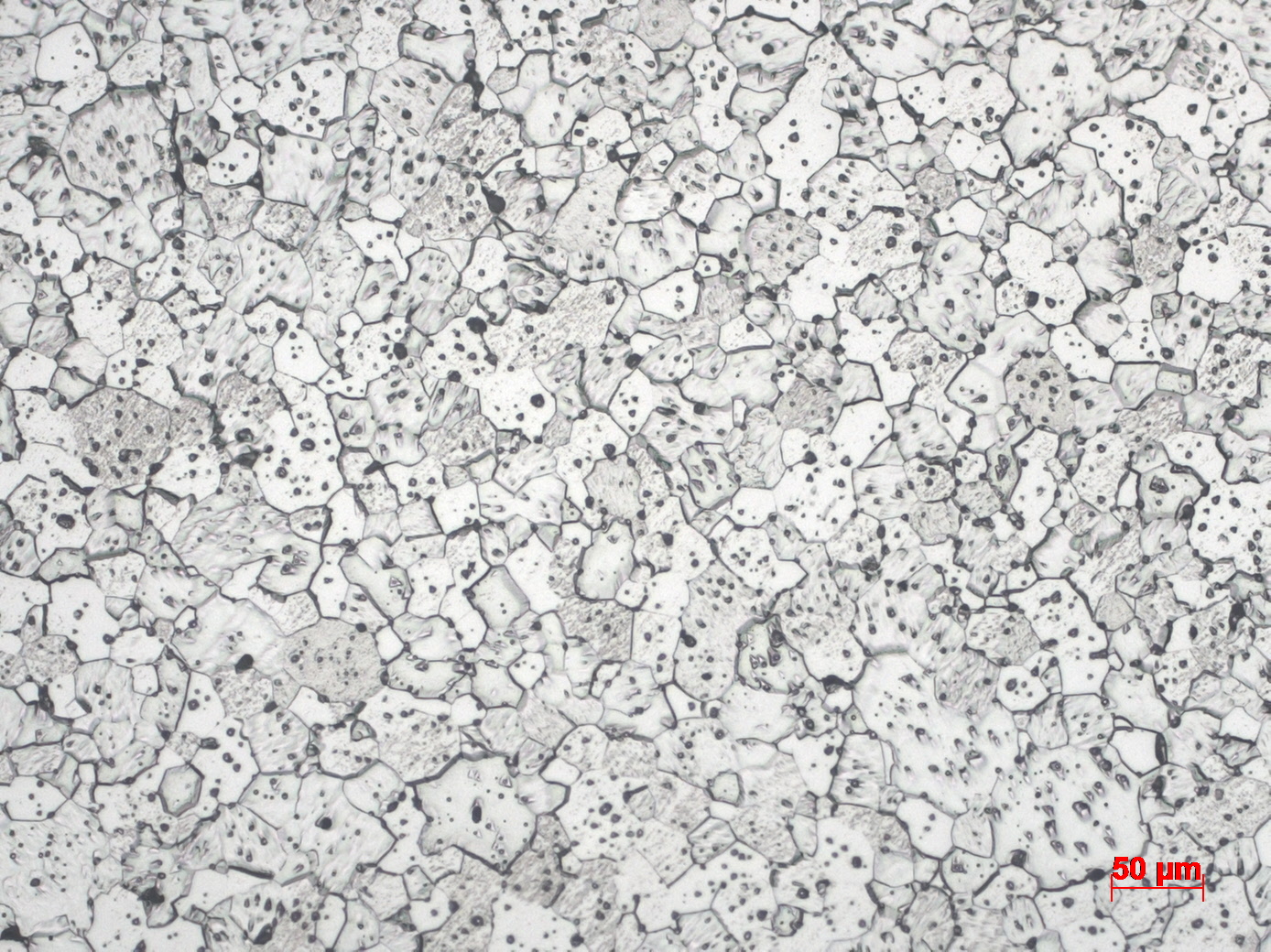

纳米粉末具有粒度较小、比表面积较高的特点,因此表面能较大,烧结活性较高,容易在低温环境下烧结达到致密的效果。但是同时纳米粉末需要克服一定的缺陷:纳米粉末颗粒具有较强的吸附作用,在使用的过程中容易引入杂质;团聚现象会更为严重;粉体堆积密度过低。为了探究纳米粉添加对钨制品性能的影响,项目组在制备钨制品过程中添加不同量的纳米粉,在较低烧结温度及其他同等工艺条件下制备得到钨制品。添加纳米粉,对钨制品致密度有提升作用且晶粒可显著细化。但是随着纳米粉的添加量进一步增多,钨制品的密度降低,晶粒细化作用也不再明显。

Nano powder has the characteristics of small particle size and high specific surface area, so the surface energy is large, the sintering activity is high, and it is easy to sinter in a low temperature environment to achieve a compact effect. But at the same time, nano powders need to overcome certain shortcomings: nano powder particles have a strong adsorption effect, and impurities are easily introduced in the process of use; agglomeration phenomenon will be more serious; powder bulk density is too low. In order to explore the influence of nano powder addition on the performance of tungsten products, the project team added different amounts of nano powder during the preparation of tungsten products, and prepared tungsten products under lower sintering temperature and other equivalent process conditions. Adding nano-powder can improve the density of tungsten products and the crystal grains can be significantly refined. However, as the amount of nano-powder added further increases, the density of tungsten products decreases, and the effect of grain refinement is no longer obvious.