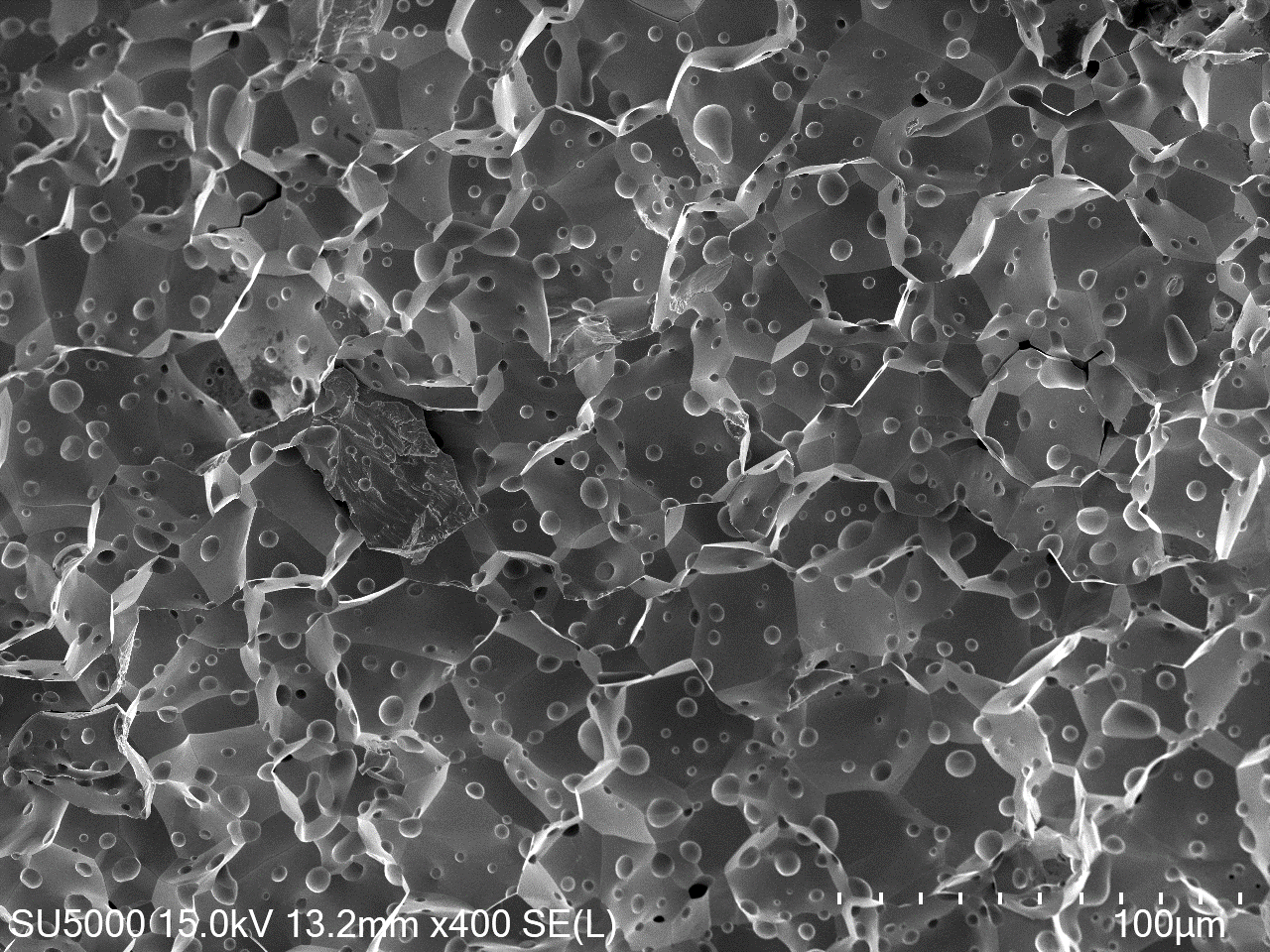

随机抽取烧结后钨坩埚样品进行解剖,取不同部位样品进行性能分析,以初步探究得到加工过程中钨坩埚不同部位微观组织变化机理。从钨坩埚对称轴中心不同部位截取4块样品,对样品进行密度及微观组织分析。制备得到的钨坩埚密度整体较为均匀,但是坩埚拐角处密度较低。为进一步分析上述现象,对钨坩埚不同部位样品边缘部位和芯部进行微观形貌观察,钨坩埚整体微观组织较为均匀,但拐角处内外侧晶粒尺寸差别较大,边缘处晶粒尺寸大于芯部尺寸。

Samples of sintered tungsten crucibles were randomly selected for dissection, and samples of different parts were taken for performance analysis, in order to initially explore the mechanism of microstructure changes in different parts of the tungsten crucible during processing. Four samples were taken from different parts of the center of the tungsten crucible symmetry axis, and the samples were analyzed for density and microstructure. The density of the prepared tungsten crucible is relatively uniform overall, but the density at the corners of the crucible is low. In order to further analyze the above phenomenon, the micro morphology of the edge and core of the sample at different parts of the tungsten crucible was observed. The overall microstructure of the tungsten crucible was relatively uniform, but the grain size at the inner and outer corners differed greatly, and the grain size at the edge was larger than that of the core. 部Dimensions.