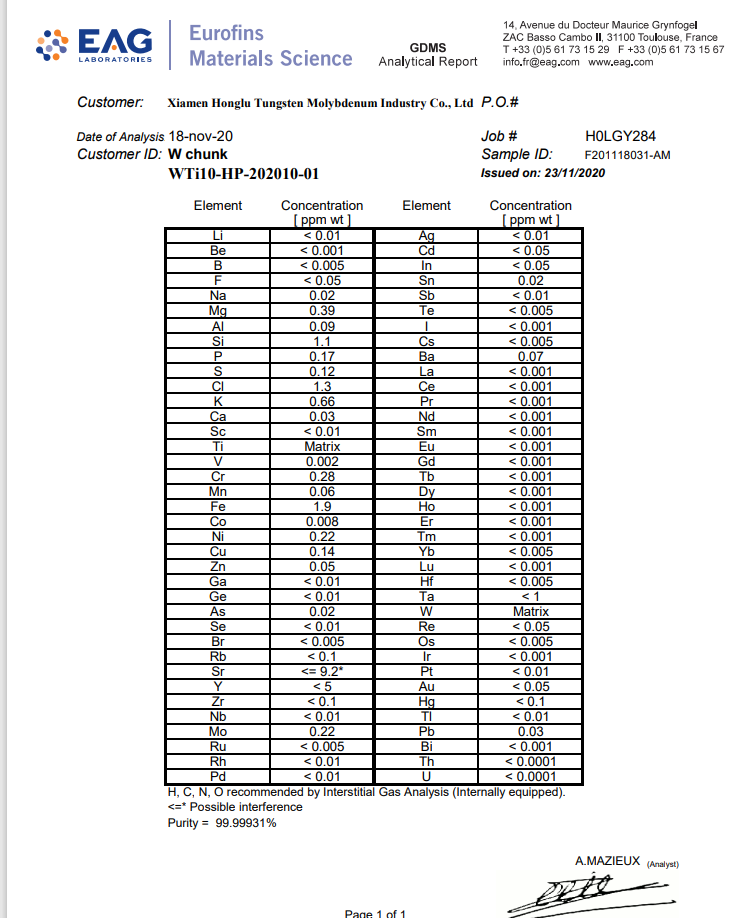

取称量后的超高纯W及高纯Ti/TiH2粉末,其中TiH2在“Ti”成分中占比39%~100%,放入混合了一定比例钨球的V型混料机进行均匀混料,物料以钛箔包裹后置于石墨模具,在真空热压炉内开展高温高压烧结试验,选取烧结温度1400℃、压力25MPa、保温时间60min,并在700 ℃时保温1.5~3.5 h。测试烧结样品的气体及碱金属杂质含量。采用碳硫分析仪、氧氮氢分析仪检测样品中C、S、O、N、H含量,辉光放电质谱法(GDMS)分析烧结钨合金中的碱金属等各类杂质含量。

After weighing, ultra-high purity W and high purity Ti/TiH2 powders, in which TiH2 accounted for 39%~100% in the "Ti" composition, were put into a V-shaped mixer mixed with a certain proportion of tungsten spheres for uniform mixing. The materials were wrapped with titanium foil and placed in graphite mold, and sintering tests were carried out at high temperature and high pressure in vacuum hot pressing furnace. Sintering temperature 1400℃, pressure 25MPa, holding time 60min, and holding time 1.5-3.5 h at 700 ℃ were selected. Test the content of gas and alkali metal impurities in sintered samples. The contents of C, S, O, N and H in the samples were detected by carbon sulfur analyzer and oxygen nitrogen hydrogen analyzer, and the contents of alkali metals and other impurities in the sintered tungsten alloy were analyzed by gD-MS.