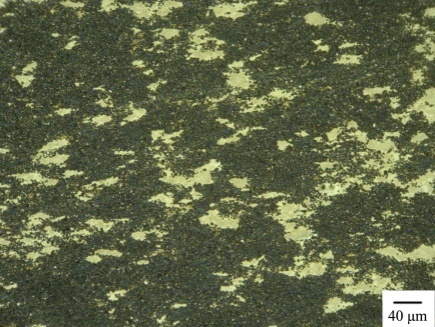

取称量后的超高纯W及高纯Ti/TiH2粉末,其中TiH2在“Ti”成分中占比39%~90%,放入混合一定比例钨球的V型混料机进行均匀混料,物料以钛箔包裹后置于石墨模具,在真空热压炉内开展高温高压烧结试验,选取烧结温度1400℃、压力25MPa、保温时间60min,并在700 ℃时保温3.5 h。采用金相显微镜分析不同原料配比对金相组织的影响。

After weighing, ultra-high purity W and high purity Ti/TiH2 powders, in which TiH2 accounts for 39%~90% of the "Ti" composition, were put into a V-shaped mixer that mixed tungsten spheres with a certain proportion for uniform mixing. The materials were wrapped with titanium foil and placed in graphite mold, and sintering tests were carried out at high temperature and high pressure in vacuum hot pressing furnace. Sintering temperature 1400℃, pressure 25MPa, holding time 60min, and holding time 3.5 h at 700 ℃ were selected. Metallographic microscope was used to analyze the effect of different raw material ratio on metallographic structure.