采用有限元方法对多元硅合金粉的压实和烧结过程进行了数值模拟,包括单向模压、单向热压和双向热压。系统地讨论及研究了多元硅合金靶材的初始堆积结构、压实方法、压实压力和烧结温度与整体相对密度的关系。同时,对多元硅合金粉的宏观和微观性能进行了表征,如整体和局部相对密度、局部应力分布和空穴填充行为。结果表明,采用单轴热压或双向热压方法均可获得内应力较低的高致密性多元硅合金靶材。并通过物理实验验证了仿真结果的准确性。

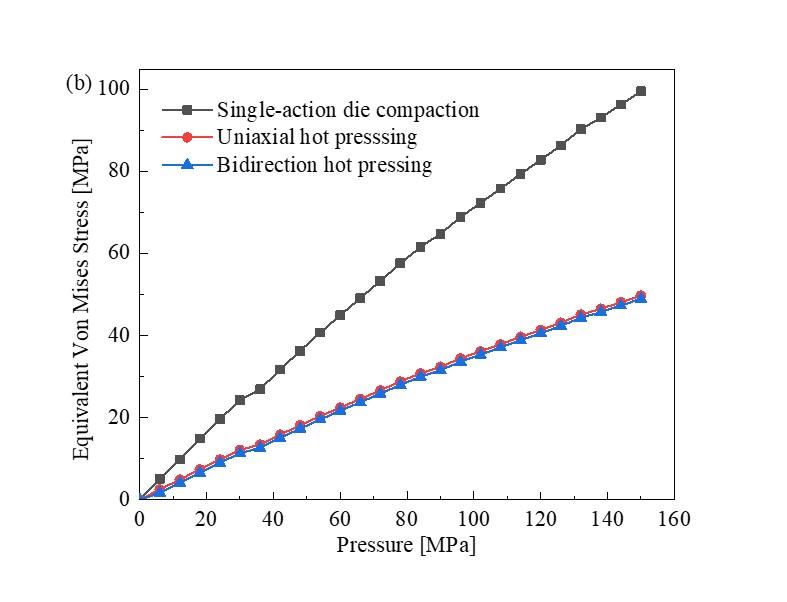

The finite element method was used to numerically simulate the compaction and sintering process of multi-element silicon alloy powder, including one-way molding, one-way hot pressing and two-way hot pressing. The relationship between the initial stacking structure, compaction method, compaction pressure, sintering temperature and overall relative density of the multi-element silicon alloy target is systematically discussed and studied. At the same time, the macro and micro properties of the multi-element silicon alloy powder were characterized, such as overall and local relative density, local stress distribution and hole filling behavior. The results show that either uniaxial hot pressing or bidirectional hot pressing can obtain high-density multi-element silicon alloy targets with lower internal stress. And verify the accuracy of the simulation results through physical experiments.