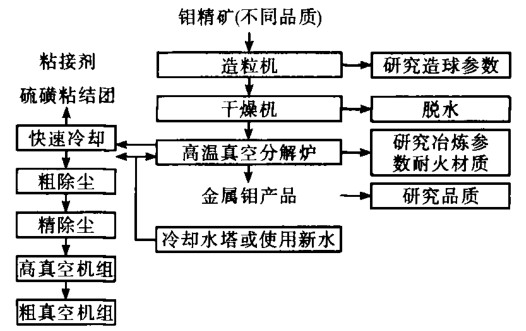

利用MoS2真空高温分解高效制备钼粉的工艺特性,提出了真空分解炉的基本结构和工作原理,并采用热平衡法对炉体7个部位的热量损失情况进行了详细计算,为炉体功率的选择提供了理论依据。同时通过对57%的钼精矿进行分解试验,得到了预期的钼粉产品和硫磺产品。

Using the process characteristics of MoS2 vacuum high-temperature decomposition to efficiently prepare molybdenum powder, the basic structure and working principle of the vacuum decomposition furnace are proposed, and the heat loss of 7 parts of the furnace body is calculated in detail by the heat balance method, which is the choice of furnace body power Provide a theoretical basis. At the same time, through the decomposition test of 57% molybdenum concentrate, the expected molybdenum powder and sulfur products were obtained.