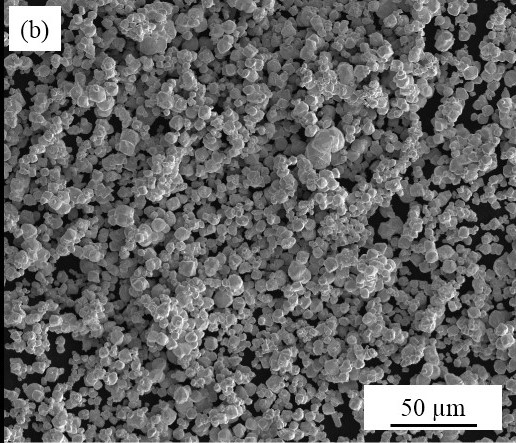

以团聚严重、不规则形状的还原钨粉为原料,经过球磨处理后,采用射频等离子体球化技术制备球形钨粉。在射频等离子体球化过程中,研究原料粉末形态对球化结果的影响。采用ZEISS Sigma 500场发射扫描电镜对球磨和球化处理前后粉末的形貌、粒度进行测试和分析。

Taking seriously agglomerated and irregularly shaped reduced tungsten powder as raw material, after ball milling treatment, spherical tungsten powder is prepared by radio frequency plasma spheroidization technology. In the process of RF plasma spheroidization, the influence of the shape of the raw material powder on the spheroidization result was studied. ZEISS Sigma 500 field emission scanning electron microscope was used to test and analyze the morphology and particle size of the powder before and after ball milling and spheroidization.