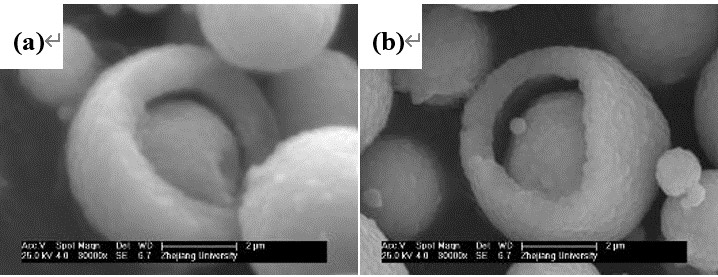

图为不同升温速率下所得二氧化钛粒子的SEM照片,其升温速率分别为5 ℃/min以及10℃/min。从图中可知,在不同的升温速率下,均可得到核壳结构的中空二氧化钛微球。但不同升温速率下所得核壳结构略有不同,在较高升温速率下所得二氧化钛微球壳层厚度相比较低升温速率所得二氧化钛微球球壳厚度略有减小。根据非平衡升温理论,升温速率的变化会对所得粉体内部结构产生非常重大的影响,在不同的升温速率下,内部结构由实心转变为多壁结构。但根据图所示,有限的升温速率变化对于结构变化的影响实际上也是非常有限的。因此,在有限的热处理条件下(无法提供足够的升温速率),通过升温速率的变化得到不同内部结构的粉体是比较困难的。因此,通过成分变化影响在相同或相近升温速率下所得粉体的内部结构是值得研究的方向。作为初步的研究,向油相溶液中引入液体石蜡作为添加剂,考察成分变化对相同升温速率下所得粉体的内部结构的影响。

The picture shows the SEM photos of titanium dioxide particles obtained at different heating rates, which are 5 ℃/min and 10℃/min respectively. It can be seen from the figure that core-shell structure hollow titanium dioxide microspheres can be obtained at different heating rates. However, the core-shell structure was slightly different at different heating rates, and the shell thickness of titanium dioxide microspheres at higher heating rates was slightly reduced compared with that at lower heating rates. According to the non-equilibrium heating theory, the change of heating rate will have a very significant impact on the internal structure of the obtained powder, and the internal structure will change from solid to multi-walled structure at different heating rates. However, as shown in the figure, the effect of a limited warming rate change on structural change is actually very limited. Therefore, under limited heat treatment conditions (unable to provide sufficient heating rate), it is difficult to obtain powders with different internal structures by changing the heating rate. Therefore, the influence of composition changes on the internal structure of the powder obtained at the same or similar heating rate is worthy of study. As a preliminary study, liquid paraffin was introduced into the oil phase solution as an additive to investigate the effect of composition changes on the internal structure of the obtained powder at the same heating rate.