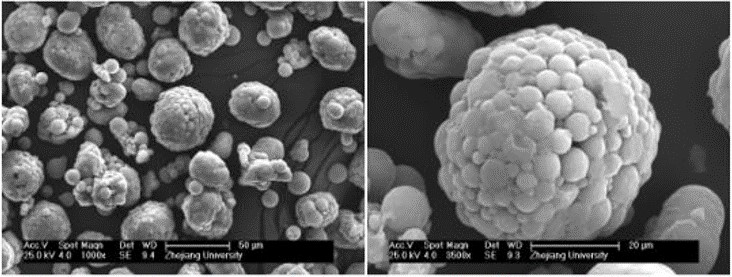

制备工艺在二氧化钛凝胶微球的制备过程中也有重要影响。首先,考察了油相溶液添加方式对所得粉体的影响。图111为向水相溶液中缓慢滴加油相溶液所得二氧化钛凝胶粒子的SEM照片。由图可知,所得粉体基本为球状粒子的聚集体。在一般的聚合物乳液制备过程中,往往经过预乳化后再添加引发剂引发聚合形成聚合物乳液。而在制备二氧化钛凝胶微球的反应体系中,乳化及溶胶凝胶反应实际上是同时进行的。若是缓慢滴加油相溶液,则先加入的油相溶液经过乳化及溶胶凝胶反应之后首先固化形成凝胶微球,而后加入的油相溶液在乳化之后仍保持着液体的流动性。在高速搅拌过程中,分散相不断发生碰撞,而液态的油相液滴在与固态的凝胶微球碰撞之后往往无法再通过高速剪切分离,因为液态油相溶液会对固态的凝胶微球产生浸润从而造成融合或者是液态油相液滴对固态凝胶微球的捕获。融合后产生的分散相粒子实际上又保持了一定的流动性,从而在之后的碰撞中不断捕获新的凝胶微球,直到体系流动性完全丧失。因此,缓慢滴加油相溶液制备的粉体具有了球状粒子的团聚结构。

The preparation process also plays an important role in the preparation of titanium dioxide gel microspheres. Firstly, the effect of adding method of oil phase solution on the obtained powder was investigated. FIG. 111 is the SEM photo of titanium dioxide gel particles obtained by slowly dropping the refueling phase solution into the aqueous phase solution. It can be seen from the figure that the obtained powder is basically the aggregate of spherical particles. In the preparation process of general polymer emulsion, it is often preemulsified and then added initiator to initiate polymerization to form polymer emulsion. In the reaction system for preparing titania gel microspheres, emulsification and sol-gel reaction are actually simultaneous. If the oil phase solution is slowly dropped, the oil phase solution added first solidifies to form gel microspheres after emulsification and sol-gel reaction, and the oil phase solution added later maintains liquid fluidity after emulsification. In the process of high-speed stirring, the dispersed phase constantly collides, and the liquid oil phase droplets often cannot be separated by high-speed shear after colliding with the solid gel microspheres, because the liquid oil phase solution will infiltrate the solid gel microspheres and cause fusion or the liquid oil phase droplets will capture the solid gel microspheres. The dispersed phase particles produced by the fusion actually maintain a certain fluidity, thus trapping new gel microspheres in subsequent collisions until the system's fluidity is completely lost. Therefore, the powder prepared by slowly dropping the oiling phase solution has the agglomeration structure of spherical particles.