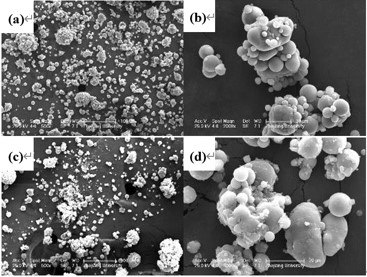

为了研究油相溶液粘度对所得粉体结构的影响,采用凡士林作为油相溶液添加剂以增加油相溶液粘度,添加量分别为原油相溶液质量的1%及3%。如图所示即为添加1 wt.%及3 wt.%凡士林后所得粉体的SEM照片。由图可知,添加凡士林之后所得粉体不再有规则的球状结构,而更多地出现了形变及扭曲的情况,并伴随有局部的团聚现象。当油相溶液粘度增大之后,其在受到高速剪切时产生形变的时间变长,而随着溶胶凝胶反应的进行,凝胶化的过程往往将这样的形变保留了下来。

In order to study the effect of the viscosity of oil phase solution on the structure of the obtained powder, petroleum jelly was used as the additive of oil phase solution to increase the viscosity of oil phase solution, and the addition amounts were 1% and 3% of the mass of oil phase solution, respectively. The figure shows the SEM photos of the powder obtained after adding 1 wt.% and 3 wt.% Vaseline. As can be seen from the figure, the powder obtained after the addition of petroleum jelly no longer has a regular spherical structure, but more deformation and distortion, and accompanied by local agglomeration phenomenon. When the viscosity of the oil phase solution increases, the deformation time under high-speed shear becomes longer, and with the sol-gel reaction, such deformation is often preserved in the gelation process.