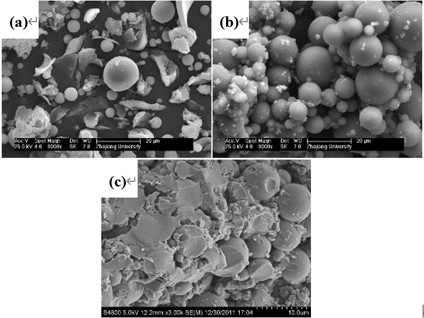

图为不同钛酸四正丁酯用量所得二氧化钛凝胶粒子的SEM照片,其中钛酸四正丁酯与乙酰乙酸乙酯摩尔比为1.0。从图中可知,钛酸四正丁酯用量对所得粉体形貌有很大影响。当油相溶液中未添加正辛醇作为溶剂,即正辛醇与钛酸四正丁酯体积比为0.0时,所得粉体呈现两种微观形貌,包括球形粒子及无规则的薄片状粒子。而当正辛醇与钛酸四正丁酯体积比为2.0时,所得粉体呈现规则的球状结构。而当两者体积比增至8.0时,则得到块状团聚,根据图中所示,其团聚体由球状粒子粘结而成。未添加正辛醇时,油相溶液由钛酸四正丁酯与乙酰乙酸乙酯组成,因此油相溶液中的钛酸四正丁酯浓度较高,因此尽管其水解速率受到乙酰乙酸乙酯的抑制,但油/水界面处反应速率仍然很高;当油相溶液加入水相并形成油状液滴时,油/水界面凝胶化形成固体球壳,而球体内部仍然为液相,若球体体积较大,则可能在高速剪切下被破坏,而若球体体积较小,则有可能在高速剪切下仍保持球状结构,故所得粉体中的薄片状粉体可能来源于被破坏的球壳,而球状粉体则可能来源于高速剪切下没有被破坏的半固化球体。而当钛酸四正丁酯浓度过低时,凝胶固化之后形成的凝胶球强度过低,从而在后续的收集过程中受力变形甚至粘结成块体。

The picture shows the SEM photos of titanium dioxide gel particles obtained by different dosage of tetrabutyl titanate, in which the molar ratio of tetrabutyl titanate to ethyl acetoacetate is 1.0. It can be seen from the figure that the amount of tetrabn-butyl titanate has a great influence on the morphology of the obtained powder. When n-octanol was not added as solvent in the oil phase solution, that is, the volume ratio of n-octanol to tetrabutyl titanate was 0.0, the obtained powder showed two kinds of microscopic morphology, including spherical particles and irregular flaky particles. When the volume ratio of n-octanol to tetra-n-butyl titanate was 2.0, the obtained powder showed regular spherical structure. When the volume ratio of the two increases to 8.0, the agglomeration is obtained. As shown in the figure, the agglomeration is formed by the bonding of spherical particles. When n-octanol was not added, the oil phase solution was composed of tetrabn-butyl titanate and ethyl acetoacetate, so the concentration of tetrabn-butyl titanate in the oil phase solution was high, so the reaction rate at the oil/water interface was still high, although its hydrolysis rate was inhibited by ethyl acetoacetate. When the oil phase solution is added to the water phase to form an oil-like drop, the oil/water interface gels to form a solid spherical shell, while the inside of the sphere is still a liquid phase. If the sphere has a large volume, it may be destroyed under high-speed shear, while if the sphere has a small volume, it may still maintain a spherical structure under high-speed shear. Therefore, the flaky powder in the obtained powder may come from the destroyed spherical shell. The spherical powder may come from semi-cured spheres that are not destroyed under high-speed shear. However, when the concentration of tetrabutyl titanate is too low, the strength of the gel ball formed after gel curing is too low, so that in the subsequent collection process, the force deformation and even the bond into a block.