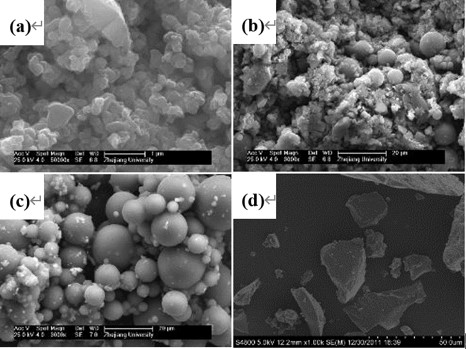

图为不同乙酰乙酸乙酯用量所得二氧化钛凝胶粒子的SEM照片,从图中可以看出,乙酰乙酸乙酯添加量的变化对最终产物的形态有很大影响。随着乙酰乙酸乙酯与钛酸四正丁酯摩尔比由0.0增至1.0,所得粉体微观形态由无规则结构向球形转变,而进一步增加两者摩尔比至2.0时,所得粉体则为块状无规则结构。钛酸四正丁酯遇水易水解,而乙酰乙酸乙酯作为螯合剂,可有效抑制钛酸四正丁酯的水解。未添加乙酰乙酸乙酯时,将含有钛酸四正丁酯的油相溶液直接加入到水相之中,则导致在油相溶液充分乳化之前,钛酸四正丁酯迅速水解,从而得到无规则的粉体。当添加乙酰乙酸乙酯时,钛酸四正丁酯的水解被抑制,从而可保证油相溶液凝胶化之前,经过了充分乳化而形成球状结构。过量添加乙酰乙酸乙酯将导致钛酸四正丁酯水解过度抑制,在经过24小时的反应之后仍然无法凝胶固化,从而导致在抽滤过程中未完全固化粉体受力后粘结,即如图中所得块状无规则粉体。

The picture shows the SEM photos of titanium dioxide gel particles obtained with different amounts of ethyl acetoacetate. It can be seen from the figure that the change of the amount of ethyl acetoacetate has a great influence on the morphology of the final product. As the molar ratio of ethyl acetoacetate to tetrabutyl titanate increased from 0.0 to 1.0, the microstructure of the obtained powder changed from irregular structure to spherical structure, and when the molar ratio of the two was further increased to 2.0, the obtained powder showed a massive irregular structure. Tetrabutyltitanate is easily hydrolyzed in water, and ethyl acetoacetate, as a chelating agent, can effectively inhibit the hydrolysis of tetrabutyltitanate. When ethyl acetoacetate is not added, the oil phase solution containing tetrabutyl titanate is directly added to the water phase, resulting in rapid hydrolysis of tetrabutyl titanate before the oil phase solution is fully emulsified, resulting in irregular powder. When ethyl acetoacetate is added, the hydrolysis of tetra-n-butyl titanate is inhibited, thus ensuring that the oil phase solution is fully emulsified to form a spherical structure before gelation. Excessive addition of ethyl acetoacetate will lead to excessive inhibition of tetra-n-butyl titanate hydrolysis, which still cannot gel cure after 24 hours of reaction, resulting in the bonding of the incomplete cured powder after stress in the extraction and filtration process, that is, the massive irregular powder obtained in the figure.