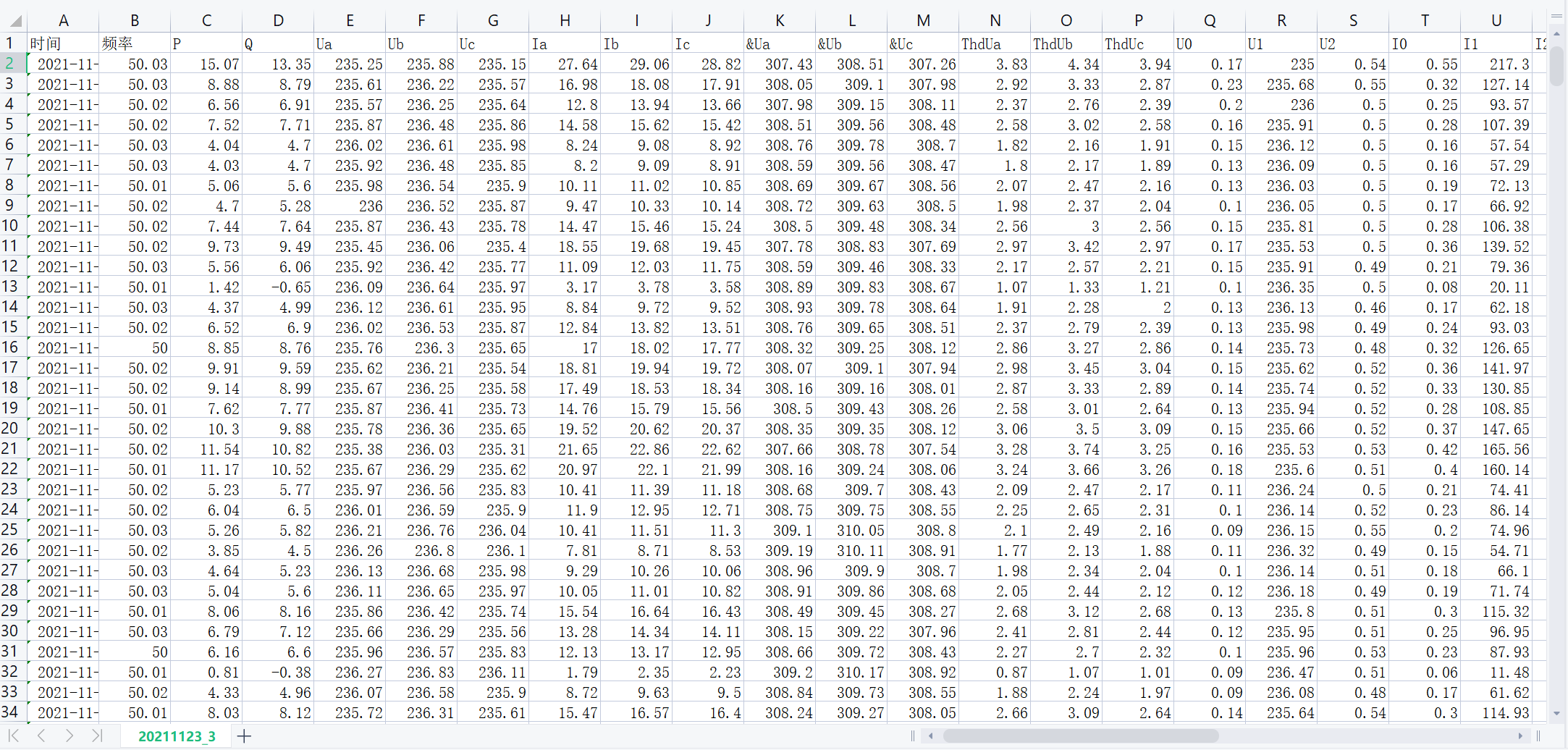

中国科学院电工研究所依据国家重点研发计划项目“废旧智能装备机电一体化再制造升级技术”课题四——“再制造产品服役过程健康状态在线监测技术”的任务要求,研发了适用于再制造直接起动永磁同步电动机等多种类型再制造电机服役状态监测的综合检测装置(型号规格:IDDEM-01),该装置采用测试范围0A~100A(精度± 0.2 %)的电流钳、耐压3000V的电压夹、温度测量范围-50 ~ +150 ℃的贴片式温度传感器、转速测量范围1~10000rps的光电转速传感器和振速检测范围:0 ~ 20 mm/s及加速度测量范围:±4g的振动传感器,检测电机的电流、电压、转速、温度、振动等多类型在线运行参数。对由京津冀再制造产业技术研究院研制并在北京建工土木工程有限公司投入运行的一台再制造30kW三相永磁同步电动机进行了现场运行数据的检测,运行电压为380V,最大运行功率14kW,于2021年11月23日15时完成现场装置与检测电机的测试接线并启动连续监测至2021年12月8日16时结束,连续运行16天,约385小时,形成数据近130万条,数据起始文件为“电动机 应用1.xlsx”,依次为“应用2”至“应用7”,数据结束文件为“电动机 应用7.xlsx”。

本文件为中间阶段“应用3”。

According to the task requirements of the national key research and development plan project "Electromechanical integration remanufacturing upgrade technology for waste intelligent equipment"-"On-line monitoring technology for health status of remanufactured products in service", the Institute of Electrotechnics of Chinese Academy of Sciences has developed a comprehensive detection device (model specification: IDDEM-01) suitable for monitoring the service status of various types of remanufactured motors such as remanufactured direct-start permanent magnet synchronous motors. The device adopts a current clamp with a test range of 0A~100A (accuracy 0.2%), a voltage clamp with a withstand voltage of 3,000 V, a patch temperature sensor with a temperature measurement range of -50 ~ +150℃, a photoelectric speed sensor with a speed measurement range of 1 ~ 1~10000rps, and a vibration sensor with a vibration speed detection range of 0 ~ 20 mm/s and an acceleration measurement range of 4g. The field operation data of a remanufactured 30kW three-phase permanent magnet synchronous motor developed by Beijing-Tianjin-Hebei Remanufacturing Industry Technology Research Institute and put into operation in Beijing Jiangong Civil Engineering Co., Ltd. were tested, with an operating voltage of 380V and a maximum operating power of 14kW. The test wiring of the field device and the testing motor was completed at 15: 00 on November 23, 2021, and continuous monitoring was started until 16: 00 on December 8, 2021. After continuous operation for 16 days, about 385 hours, nearly 1.3 million pieces of data were formed. The starting file of data was "Motor Application 1.xlsx", followed by "Application 2" to "Application 7", and the ending file was "Motor Application 7.xlsx".

This document is the intermediate stage "Application 3".