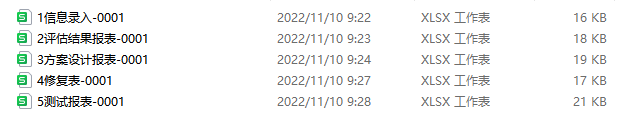

1、废旧机器人进场后的信息录入,录入到废旧机器人再制造示范线信息管理软件,用于追溯废旧机器人再制造前的历史信息,包含录入人员,时间,机器人编号,废旧机器人类型,厂家,型号,现状,使用历史等。

2、废旧机器人进行综合评估后的信息记录,录入到废旧机器人再制造示范线信息管理软件,用于记录废旧机器人的故障信息,包括废旧机器人柜体,控制器,示教器,伺服驱动器,其他功能模块,线束与接插件,本体铸件,减速器,电气,传动机构等的评估,并进行一个整体情况说明。

3、废旧机器人再制造方案设计,依据废旧机器人再制造示范线信息管理软件进行设计,并记录到软件中,使废旧机器人再制造人员有据可依,主要包括柜体、控制器、示教器、伺服驱动器、其他功能模块、线束与接插件、本体铸件、减速器、电机、传动机构等的再制造方案设计,并进行整机再制造方案设计说明。

4、废旧机器人再制造过程记录,再制造过程录入到废旧机器人再制造示范线信息管理软件中,使机器人的再制造过程可查询,可追溯,包括柜体、控制器、示教器、伺服、其他功能模块、本体铸件、电机、减速机、机械伺服、线束与接插件等的再制造过程记录,已经整机再制造过程记录。

5、废旧机器人再制造后的整机测试记录,将测试结果录入到废旧机器人再制造示范线信息管理软件中,为再制造机器人的销售,提供性能依据,主要包括外观结构、按钮显示联锁、运动功能、姿态特性—单轴、姿态特性—末轴、稳定性测试等。

1. Input the information of the used robot after entering the site into the information management software of the demonstration line of the used robot remanufacturing, which is used to trace the historical information of the used robot before the remanufacturing, including the input personnel, time, robot number, type of the used robot, manufacturer, model, current situation and use history.

2. The information record of the waste robot after comprehensive evaluation is entered into the waste robot remanufacturing demonstration line information management software, which is used to record the fault information of the waste robot, including the evaluation of the waste robot cabinet, controller, demonstrator, servo driver, other functional modules, wiring harness and connector, body casting, reducer, electrical, transmission mechanism, etc. And give an overall situation description.

3. Design the waste robot remanufacturing scheme according to the waste robot remanufacturing demonstration line information management software, and record it in the software, so that the waste robot remanufacturing personnel can rely on it. It mainly includes the remanufacturing scheme design of cabinet, controller, demonstrator, servo driver, other functional modules, wiring harness and connector, body casting, reducer, motor, transmission mechanism, etc., and the whole machine remanufacturing scheme design description.

4. Records of the remanufacturing process of the used robot are recorded into the information management software of the remanufacturing demonstration line of the used robot, so that the remanufacturing process of the robot can be inquired and traced, including the records of the remanufacturing process of the cabinet, controller, demonstrator, servo, other functional modules, body casting, motor, reducer, mechanical servo, wire harness and connector, etc. The whole machine remanufacturing process has been recorded.

5. Test records of the whole machine after the remanufacturing of the used robot, input the test results into the information management software of the remanufacturing demonstration line of the used robot, and provide performance basis for the sales of the remanufacturing robot, mainly including the appearance structure, button display interlock, motion function, attitude characteristics - single axis, attitude characteristics - final axis, stability test, etc.