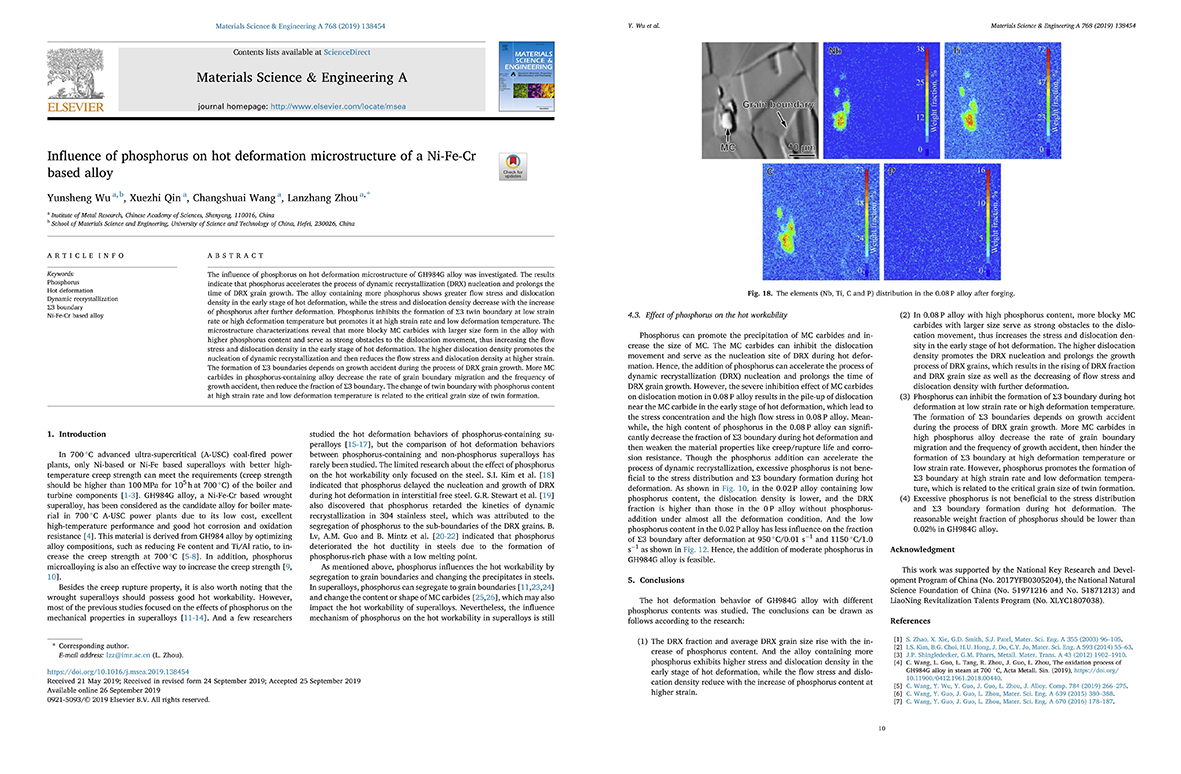

The influence of phosphorus on hot deformation microstructure of GH984G alloy was investigated. The results indicate that phosphorus accelerates the process of dynamic recrystallization (DRX) nucleation and prolongs the time of DRX grain growth. The alloy containing more phosphorus shows greater flow stress and dislocation density in the early stage of hot deformation, while the stress and dislocation density decrease with the increase of phosphorus after further deformation. Phosphorus inhibits the formation of Σ3 twin boundary at low strain rate or high deformation temperature but promotes it at high strain rate and low deformation temperature. The microstructure characterizations reveal that more blocky MC carbides with larger size form in the alloy with higher phosphorus content and serve as strong obstacles to the dislocation movement, thus increasing the flow stress and dislocation density in the early stage of hot deformation. The higher dislocation density promotes the nucleation of dynamic recrystallization and then reduces the flow stress and dislocation density at higher strain. The formation of Σ3 boundaries depends on growth accident during the process of DRX grain growth. More MC carbides in phosphorus-containing alloy decrease the rate of grain boundary migration and the frequency of growth accident, then reduce the fraction of Σ3 boundary. The change of twin boundary with phosphorus content at high strain rate and low deformation temperature is related to the critical grain size of twin formation.