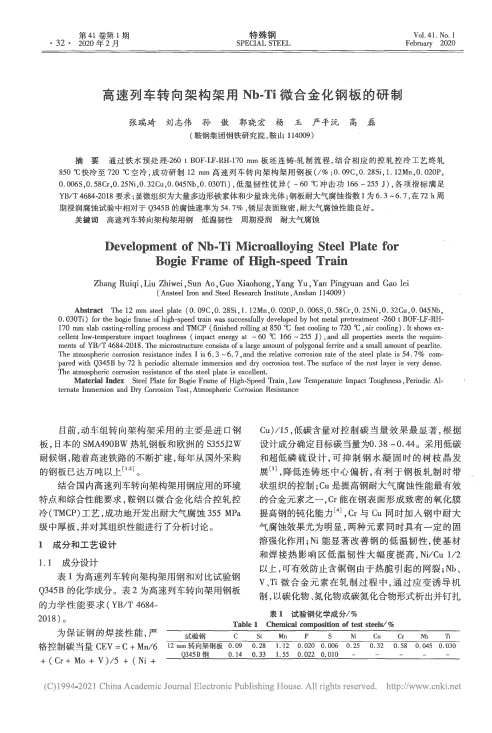

通过铁水预处理-260 t BOF-LF-RH-170mm板坯连铸-轧制流程,结合相应的控轧控冷工艺终轧850℃快冷至720℃空冷,成功研制12mm高速列车转向架构架用钢板(/%:0.09C,0.28Si,1.12Mn,0.020P,0.006S,0.58Cr,0.25Ni,0.32Cu,0.045Nb,0.030Ti),低温韧性优异(-60℃冲击功166~255 J),各项指标满足YB/T 4684-2018要求;显微组织为大量多边形铁素体和少量珠光体;钢板耐大气腐蚀指数I为6.3~6.7,在72 h周期浸润腐蚀试验中相对于Q345B的腐蚀速率为54.7%,锈层表面致密,耐大气腐蚀性能良好。