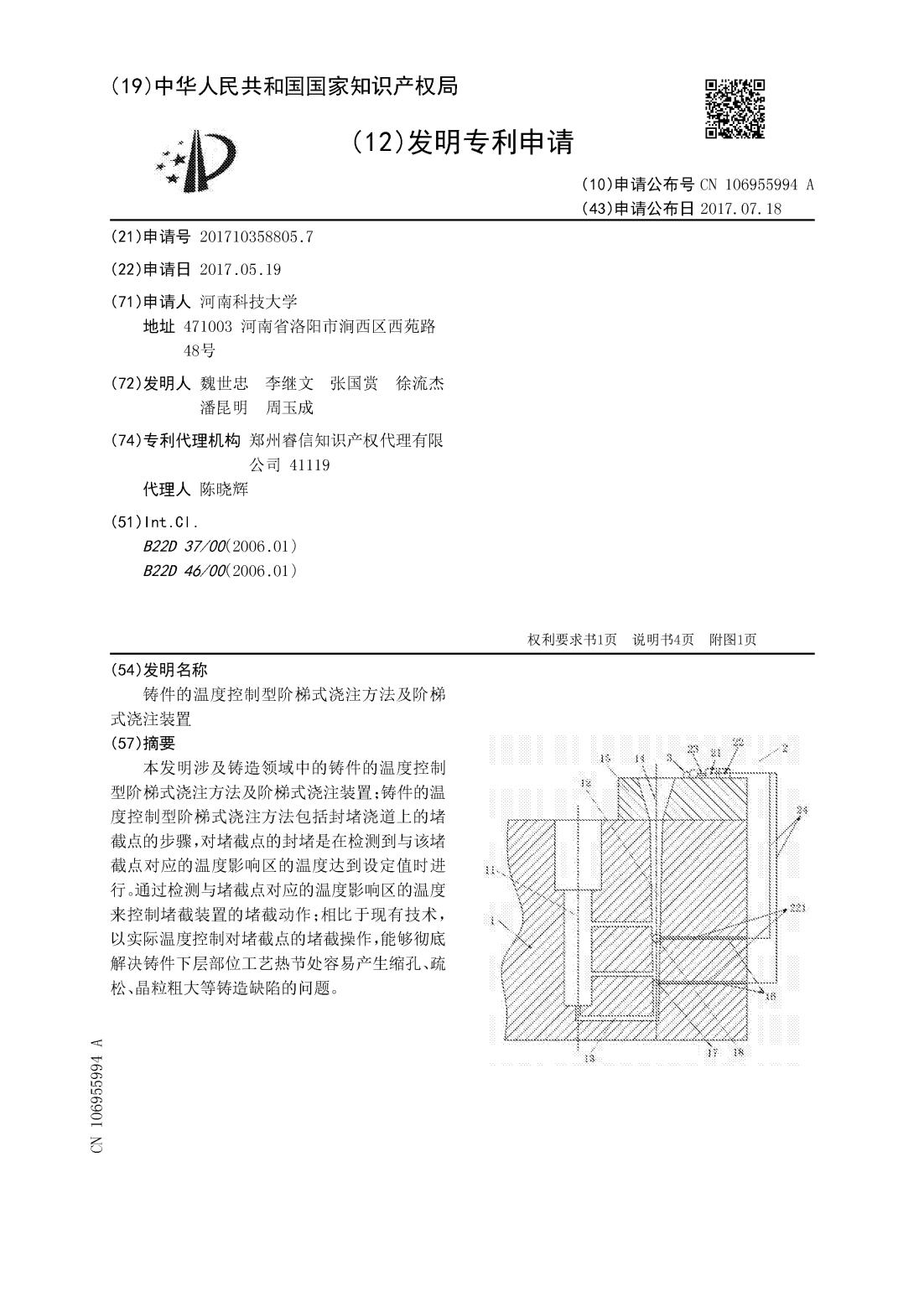

本发明涉及铸造领域中的铸件的温度控制型阶梯式浇注方法及阶梯式浇注装置;铸件的温度控制型阶梯式浇注方法包括封堵浇道上的堵截点的步骤,对堵截点的封堵是在检测到与该堵截点对应的温度影响区的温度达到设定值时进行。通过检测与堵截点对应的温度影响区的温度来控制堵截装置的堵截动作;相比于现有技术,以实际温度控制对堵截点的堵截操作,能够彻底解决铸件下层部位工艺热节处容易产生缩孔、疏松、晶粒粗大等铸造缺陷的问题。

The invention relates to a temperature-controlled type stepped pouring method and stepped pouring device of casting pieces. The temperature-controlled type stepped pouring method of the casting pieces comprises a step of blocking interception points on a sprue, wherein the blocking of the interception points is carried out when the temperature of a temperature influence area corresponding to the interception points reaches a setting value; and controlling an interception action of an interception device by detecting the temperature of the temperature influence area corresponding to the interception points. Compared with the prior art, the interception operation of the interception points is controlled at a practical temperature, so that the problems that casting defects such as shrinkage cavities, loosening, coarse crystal grains and the like at technological hot spots of lower layer parts of the casting pieces easily occur can be completely solved.