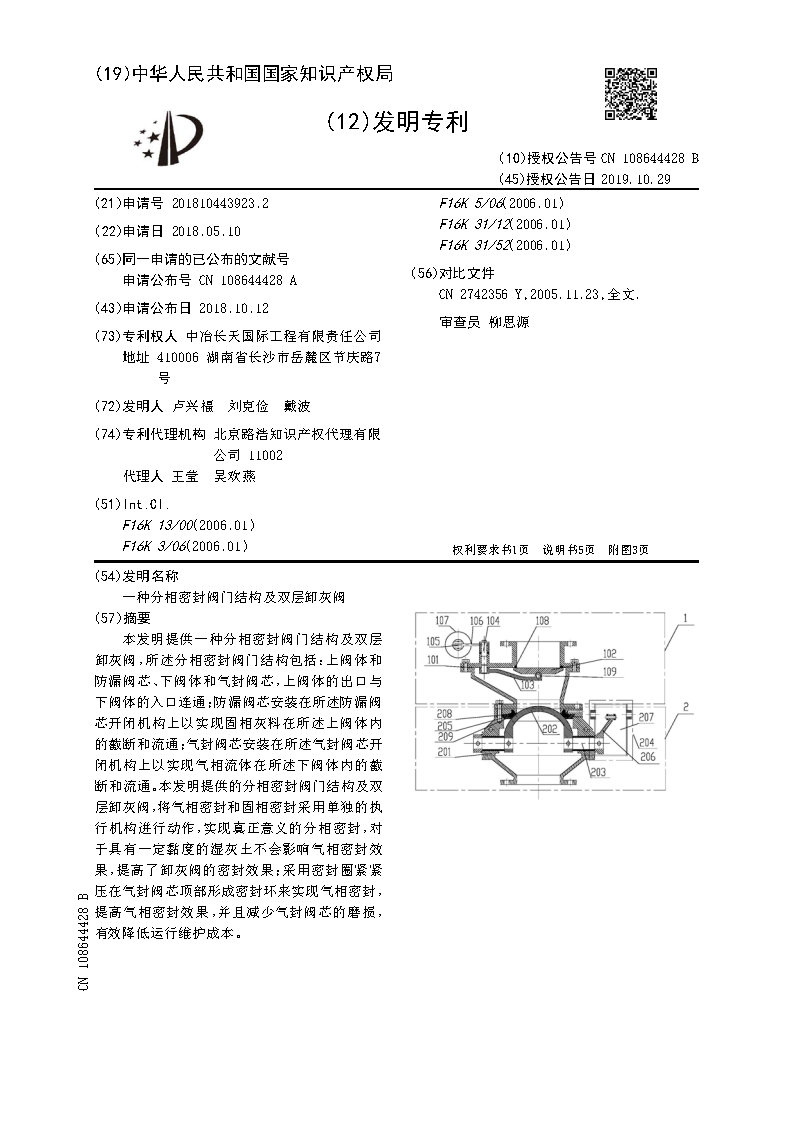

本发明提供一种分相密封阀门结构及双层卸灰阀,所述分相密封阀门结构包括:上阀体和防漏阀芯、下阀体和气封阀芯,上阀体的出口与下阀体的入口连通;防漏阀芯安装在所述防漏阀芯开闭机构上以实现固相灰料在所述上阀体内的截断和流通;气封阀芯安装在所述气封阀芯开闭机构上以实现气相流体在所述下阀体内的截断和流通。本发明提供的分相密封阀门结构及双层卸灰阀,将气相密封和固相密封采用单独的执行机构进行动作,实现真正意义的分相密封,对于具有一定黏度的湿灰土不会影响气相密封效果,提高了卸灰阀的密封效果;采用密封圈紧紧压在气封阀芯顶部形成密封环来实现气相密封,提高气相密封效果,并且减少气封阀芯的磨损,有效降低运行维护成本。

The invention provides a split phase sealing valve structure and a double-layer ash unloading valve. The split phase sealing valve structure comprises an upper valve body and a leak proof valve core, a lower valve body and an air sealing valve core, and the outlet of the upper valve body is connected with the inlet of the lower valve body; The leak proof valve core is installed on the leak proof valve core opening and closing mechanism to realize the interception and circulation of solid ash in the upper valve body; The gas seal valve core is installed on the gas seal valve core opening and closing mechanism to realize the cut-off and flow of gas phase fluid in the lower valve body. The split phase sealing valve structure and the double-layer ash unloading valve provided by the invention adopt a separate actuator to act the gas phase sealing and solid phase sealing, so as to realize the real split phase sealing, which will not affect the gas phase sealing effect for the wet ash soil with a certain viscosity and improve the sealing effect of the ash unloading valve; The sealing ring is tightly pressed on the top of the gas seal valve core to form a sealing ring to realize the gas phase sealing, improve the gas phase sealing effect, reduce the wear of the gas seal valve core and effectively reduce the operation and maintenance cost.