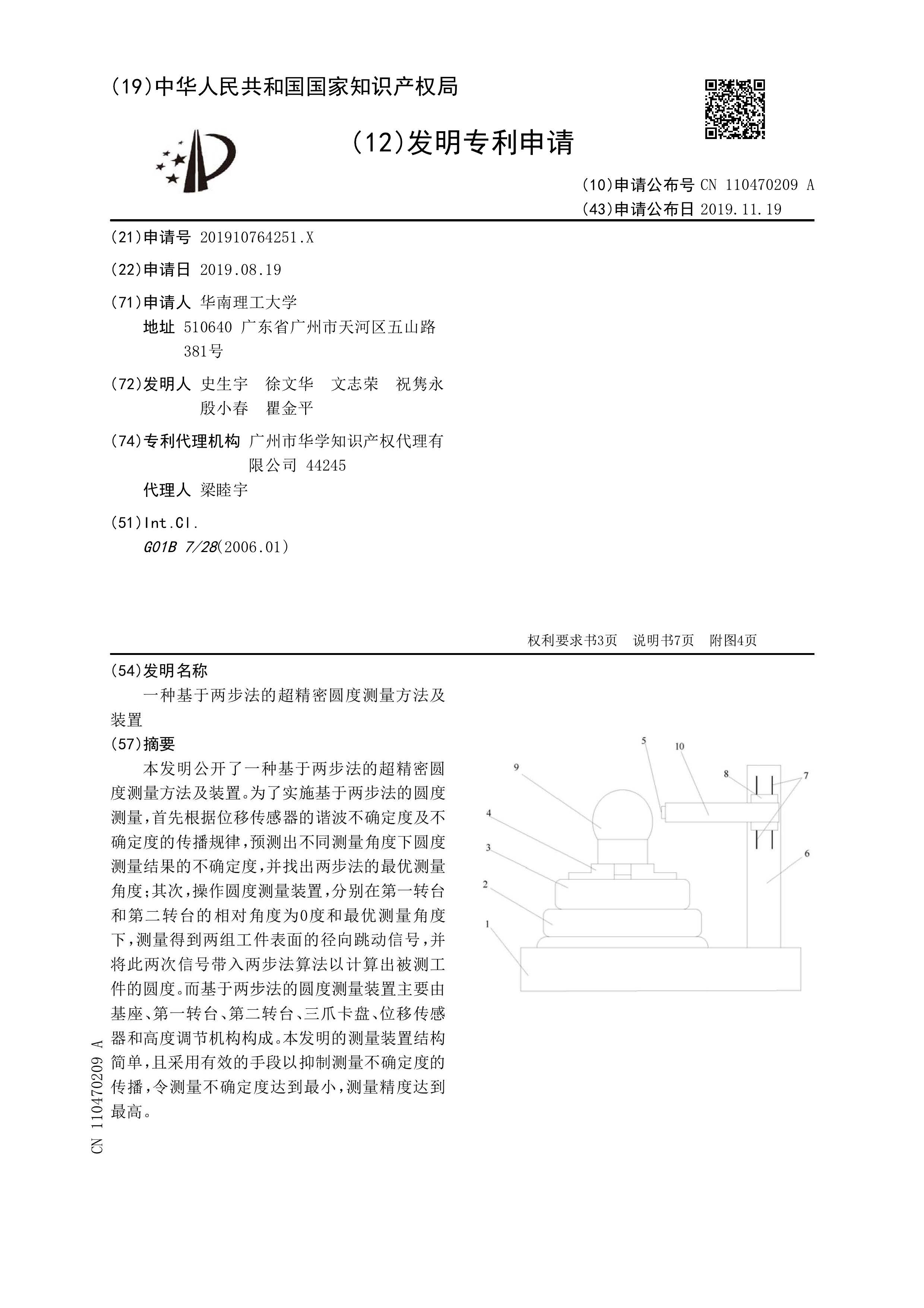

本发明公开了一种基于两步法的超精密圆度测量方法及装置。为了实施基于两步法的圆度测量,首先根据位移传感器的谐波不确定度及不确定度的传播规律,预测出不同测量角度下圆度测量结果的不确定度,并找出两步法的最优测量角度;其次,操作圆度测量装置,分别在第一转台和第二转台的相对角度为0度和最优测量角度下,测量得到两组工件表面的径向跳动信号,并将此两次信号带入两步法算法以计算出被测工件的圆度。而基于两步法的圆度测量装置主要由基座、第一转台、第二转台、三爪卡盘、位移传感器和高度调节机构构成。本发明的测量装置结构简单,且采用有效的手段以抑制测量不确定度的传播,令测量不确定度达到最小,测量精度达到最高。

The invention discloses a measurement method and device for ultra-precision roundness based on a two-step method. In order to implement roundness measurement based on the two-step method, the uncertainty of a roundness measurement result at different measurement angles is first predicted according to the uncertainty of a harmonic wave of a displacement sensor and a propagation law of the uncertainty, and an optimal measurement angle of the two-step method is found; and secondly, a roundness measurement device is operated, radial runout signals of two sets of workpiece surfaces are obtained by measurement when relative angles of a first rotary table and a second rotary table is respectively 0 degrees and the optimal measurement angle, and the two signals are brought into a two-step algorithm to calculate the roundness of a measured workpiece. The roundness measurement device based on the two-step method is mainly composed of a base, the first rotary table, the second rotary table, a three-jaw clamping disc, the displacement sensor, and a height adjustment mechanism. The measurement device of the invention is simple in structure, adopts an effective means to suppress propagation of the measurement uncertainty, so as to minimize the measurement uncertainty and to achieve the highest measurement accuracy.