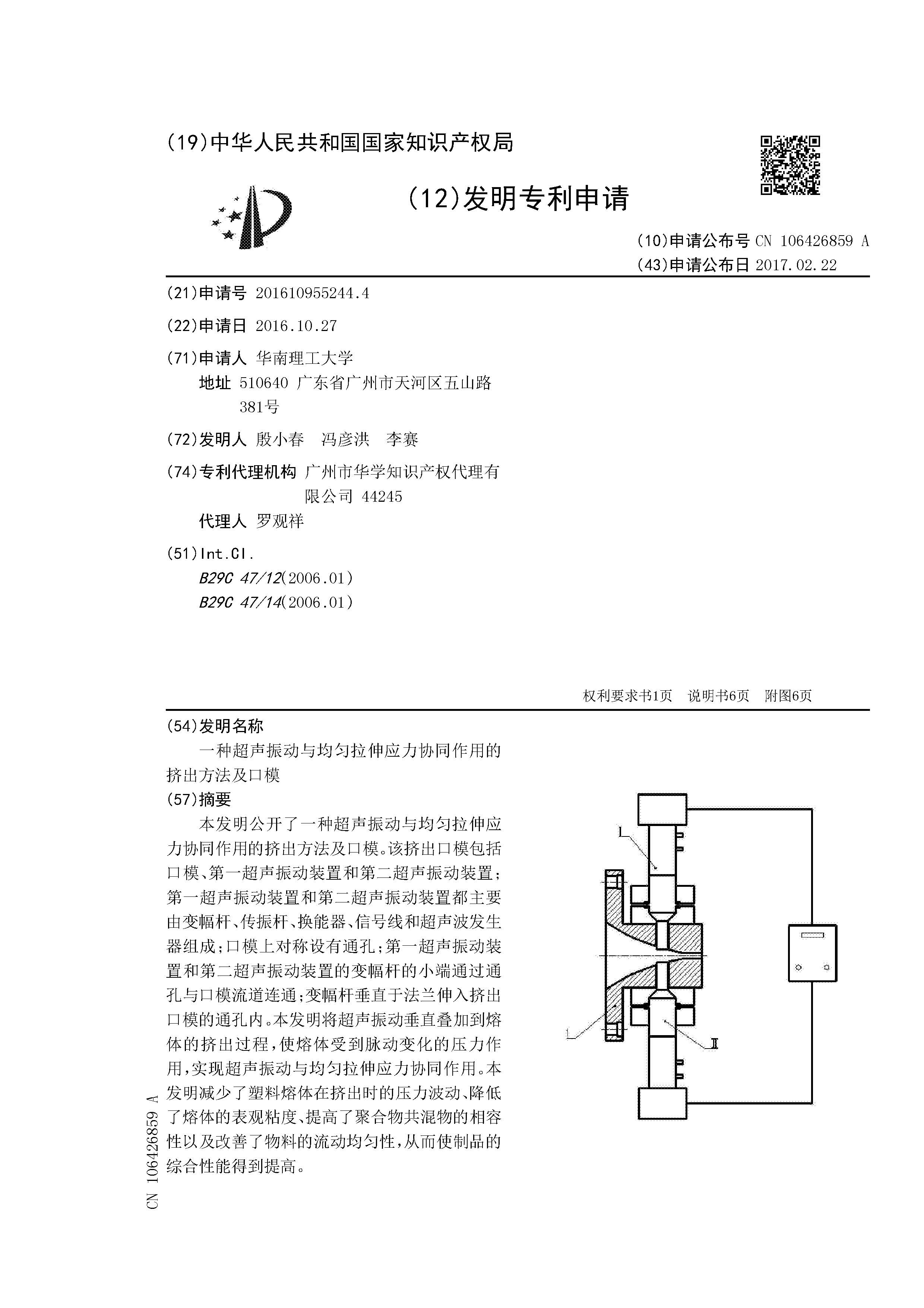

本发明公开了一种超声振动与均匀拉伸应力协同作用的挤出方法及口模。该挤出口模包括口模、第一超声振动装置和第二超声振动装置;第一超声振动装置和第二超声振动装置都主要由变幅杆、传振杆、换能器、信号线和超声波发生器组成;口模上对称设有通孔;第一超声振动装置和第二超声振动装置的变幅杆的小端通过通孔与口模流道连通;变幅杆垂直于法兰伸入挤出口模的通孔内。本发明将超声振动垂直叠加到熔体的挤出过程,使熔体受到脉动变化的压力作用,实现超声振动与均匀拉伸应力协同作用。本发明减少了塑料熔体在挤出时的压力波动、降低了熔体的表观粘度、提高了聚合物共混物的相容性以及改善了物料的流动均匀性,从而使制品的综合性能得到提高。

The invention discloses an extrusion method and die achieving the synergistic effect of ultrasonic vibration and uniform tensile stress. The extrusion die comprises a die body, a first ultrasonic vibration device and a second ultrasonic vibration device. The first ultrasonic vibration device and the second ultrasonic vibration device each mainly comprise an amplitude-change rod, a vibration transmission rod, a transducer, a signal line and an ultrasonic generator; through holes are symmetrically formed in the die body; the small ends of the amplitude-change rods of the first ultrasonic vibration device and the second ultrasonic vibration device communicate with a die runner through the through holes; and the amplitude-change rods extend into the through holes of the extrusion die in the mode of being perpendicular to flanges. Through the extrusion process that ultrasonic vibration is perpendicularly overlapped on a melt, the pressure action of pulse change acts on the melt, and the synergistic effect of ultrasonic vibration and uniform tensile stress is achieved. According to the extrusion method and die, the pressure fluctuation during extrusion of the plastic melt is reduced, the apparent viscosity of the melt is reduced, the compatibility of polymer blends is improved, the flow uniformity of materials is improved, and thus the combination property of a finished product is improved.