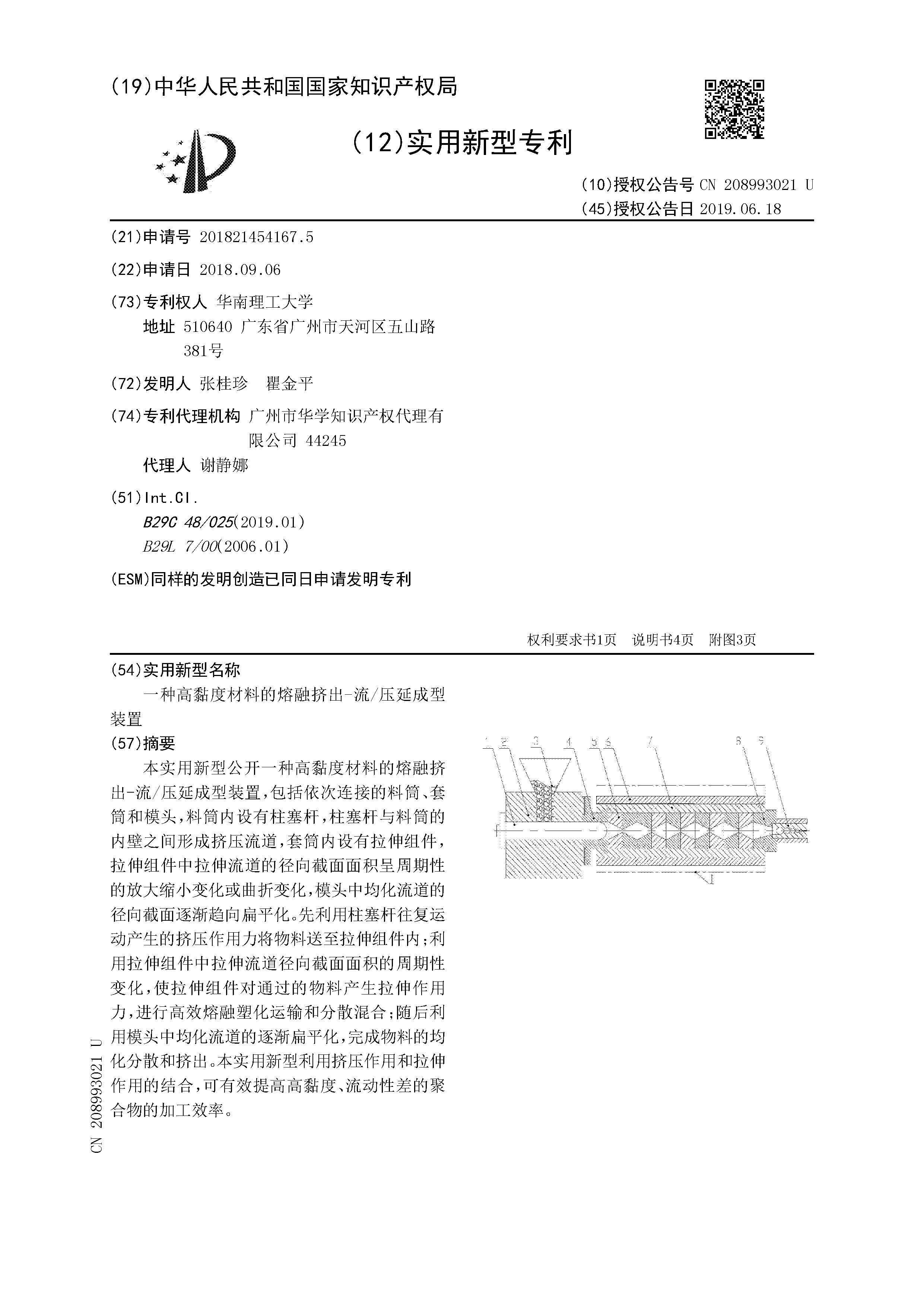

本发明公开一种高黏度材料的熔融挤出-流/压延成型方法及装置,其方法是先利用柱塞杆往复运动产生的挤压作用力将物料送至拉伸组件内;利用拉伸组件中拉伸流道径向截面面积的周期性变化,使拉伸组件对通过的物料产生拉伸作用力,进行高效熔融塑化运输和分散混合;随后利用模头中均化流道的逐渐扁平化,完成物料的均化分散和挤出。其装置包括依次连接的料筒、套筒和模头,料筒内设有柱塞杆,柱塞杆与料筒的内壁之间形成挤压流道,套筒内设有拉伸组件,拉伸组件中拉伸流道的径向截面面积呈周期性的放大缩小变化或曲折变化,模头中均化流道的径向截面逐渐趋向扁平化。本发明利用挤压作用和拉伸作用的结合,可有效提高高黏度、流动性差的聚合物的加工效率。

The invention discloses a melt extrusion-tape casting/calendering formation method and device for a high-viscosity material. The method comprises the following steps: conveying a material into a stretching assembly by virtue of an extrusion action force generated by the reciprocating motion of a plunger rod; generating a stretching action force to the passing materials through the stretching assembly by virtue of the periodical change of the radial sectional area of a stretching runner in the stretching assembly, so as to realize efficient fusion plastifying transport, dispersion and mixing; and finishing the homogenized dispersion and extrusion of the materials through the gradual flattening of a homogenization runner in a mold head. The device comprises a material cylinder, a sleeve and the mold head which are sequentially connected, wherein the plunger rod is arranged in the material cylinder, an extrusion runner is formed between the plunger rod and the inner wall of the material cylinder, the stretching assembly is arranged in the sleeve, the radial sectional area of the stretching runner in the stretching assembly is periodically amplified, shrunk or inflexed, the radial sectional area of the homogenization runner in the mold head is gradually flattened. By virtue of the combination of an extrusion effect and a stretching effect, the processing efficiency of a high-viscosity and low-fluidity polymer can be effectively improved.