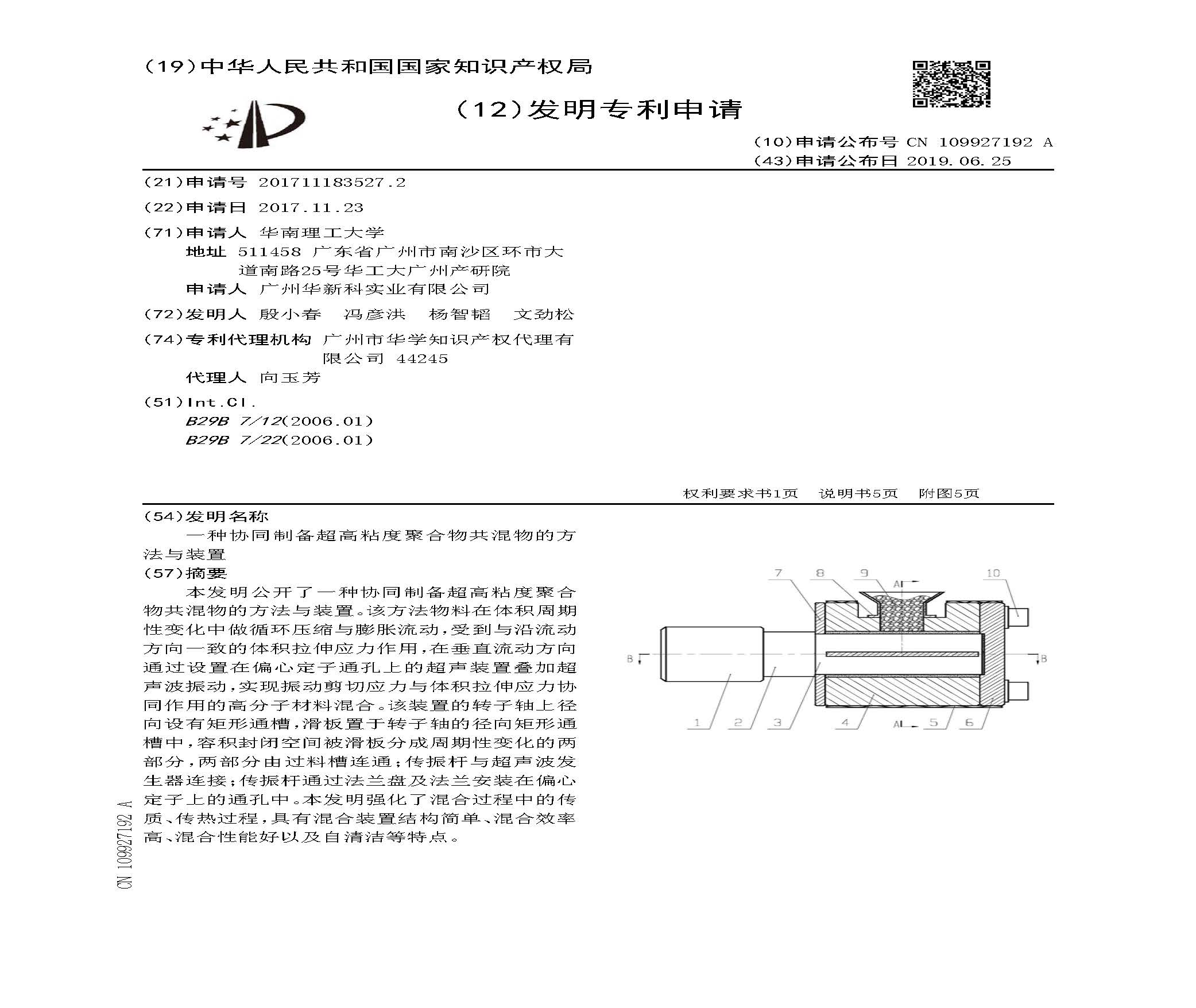

本发明公开了一种协同制备超高粘度聚合物共混物的方法与装置。该方法物料在体积周期性变化中做循环压缩与膨胀流动,受到与沿流动方向一致的体积拉伸应力作用,在垂直流动方向通过设置在偏心定子通孔上的超声装置叠加超声波振动,实现振动剪切应力与体积拉伸应力协同作用的高分子材料混合。该装置的转子轴上径向设有矩形通槽,滑板置于转子轴的径向矩形通槽中,容积封闭空间被滑板分成周期性变化的两部分,两部分由过料槽连通;传振杆与超声波发生器连接;传振杆通过法兰盘及法兰安装在偏心定子上的通孔中。本发明强化了混合过程中的传质、传热过程,具有混合装置结构简单、混合效率高、混合性能好以及自清洁等特点。

The invention discloses a method and device for synergistically preparing an ultrahigh-viscosity polymer blend. According to the method, a material flows in circularly compressed and expanding modes during periodical change of the size, and is under the size tensile stress effect in the direction consistent with the flowing direction, ultrasonic vibration is superposed in the direction perpendicular to the flowing direction through an ultrasonic device arranged at a through hole of an eccentric stator, and polymer material mixing under the synergistic effect of the vibration shear stress and the size tensile stress is achieved. A rectangular through groove is radially formed in a rotor shaft of the device, a sliding plate is placed in the radial rectangular through groove of the rotor shaft, a volume enclosure space is divided into two periodical change parts by the sliding plate, and the two parts communicate through a passing groove; a vibration transmission rod is connected with an ultrasonic generator; and the vibration transmission rod is mounted in the through hole of the eccentric stator through a flange plate and a flange. The processes of mass transfer and heat transfer in the mixing process are reinforced, and the characteristics that a mixing device is simple in structure, high in mixing efficiency, good in mixing property and capable of being automatically cleaned are achieved.