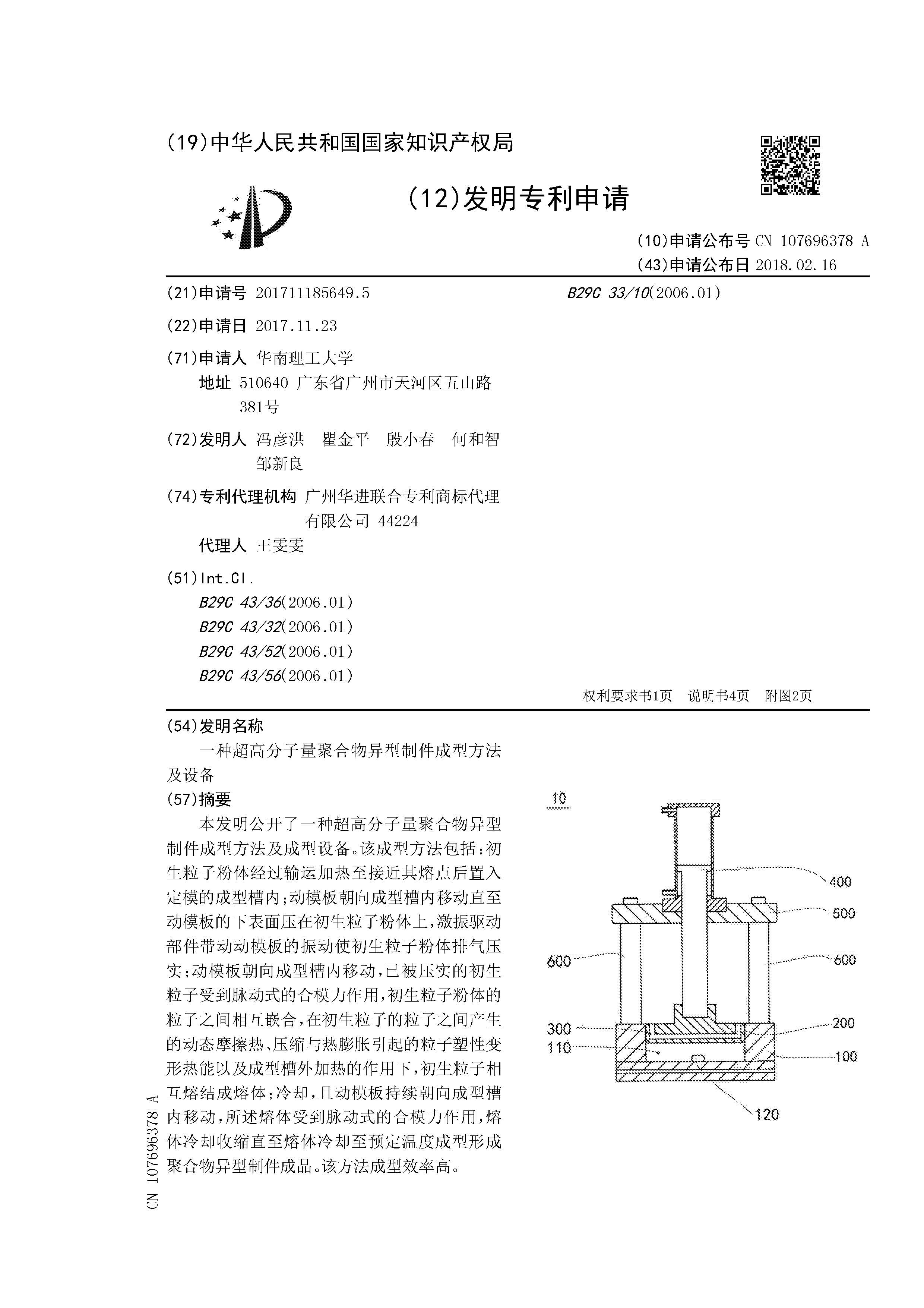

一种超高分子量聚合物异型制件成型方法,其特征在于,包括如下步骤:初生粒子粉体经过输运过程加热至接近其熔点后置入定模的成型槽内;所述定模的温度维持在所述初生粒子粉体的熔点以上且不超出该熔点以上100℃;所述动模板的温度维持在所述初生粒子粉体的熔点以上且不超出该熔点以上100℃;激振驱动部件驱动所述动模板持续朝向所述成型槽内移动,直至所述动模板的下表面接触所述初生粒子粉体时,所述激振驱动部件驱动所述动模板在朝向所述成型槽移动的同时做平行于移动方向的往复振动,所述近熔点初生粒子粉体在所述动模板的振动作用下被压实,所述初生粒子粉体之间空气由所述动模板和/或定模上设置的排气孔排出;所述激振驱动部件继续驱动所述动模板朝向所述成型槽内移动以使得所述动模板与所述成型槽之间的已被压实的所述初生粒子所受压力值达到预设值,同时激振作用引起已被压实的所述初生粒子所受压力在该压力值基础上波动,所述已被压实的初生粒子受到脉动式的合模力作用,所述初生粒子的粒子之间相互嵌合,在已被压实的所述初生粒子之间产生的动态摩擦热、压缩与热膨胀引起的粒子塑性变形热能以及所述成型槽外加热的作用下,已被压实的所述初生粒子相互熔结成熔体;所述激振驱动部件继续驱动所述动模板朝向所述成型槽内移动以使得所述动模板与所述成型槽之间的所述熔体所受压力值增大到预设值,同时持续的激振作用引起所述熔体所受压力在增大后的压力值基础上波动,所述熔体受到脉动式的合模力作用,所述定模的温度维持至结晶温度以下,所述动模板的温度维持至结晶温度以下,所述熔体冷却收缩,直至所述熔体冷却至预定温度成型形成聚合物异型制件成品。

The invention discloses a formation method and equipment for a superhigh molecular weight polymer abnormal-shape workpiece. The formation method comprises the following steps: transporting primary particle powder, heating the primary particle powder to a temperature close to the melting point, and putting the primary particle powder into a formation slot; moving a movable template towards the inside of the formation slot until the lower surface of the movable template presses the primary particle powder, and driving the movable template to vibrate by virtue of a vibration driving component soas to exhaust gas from the primary particle powder and compact the primary particle powder; moving the movable template towards the inside of the formation slot to generate a pulsed mold clamping force to the compacted primary particle powder to mutually embed particles of the primary particles, wherein the particles of the primary particles are mutually melted into a melt under the effects of particle plastic deformation heat energy caused by dynamic friction heat, compression and thermal expansion generated among the particles of the primary particles and external heat of the formation slot; and cooling, moving the movable template towards the inside of the formation slot generate a mold clamping force to the melt, cooling and shrink the melt to a preset temperature, so as to form the polymer abnormal-shape workpiece finished product. The formation method is high in formation efficiency.