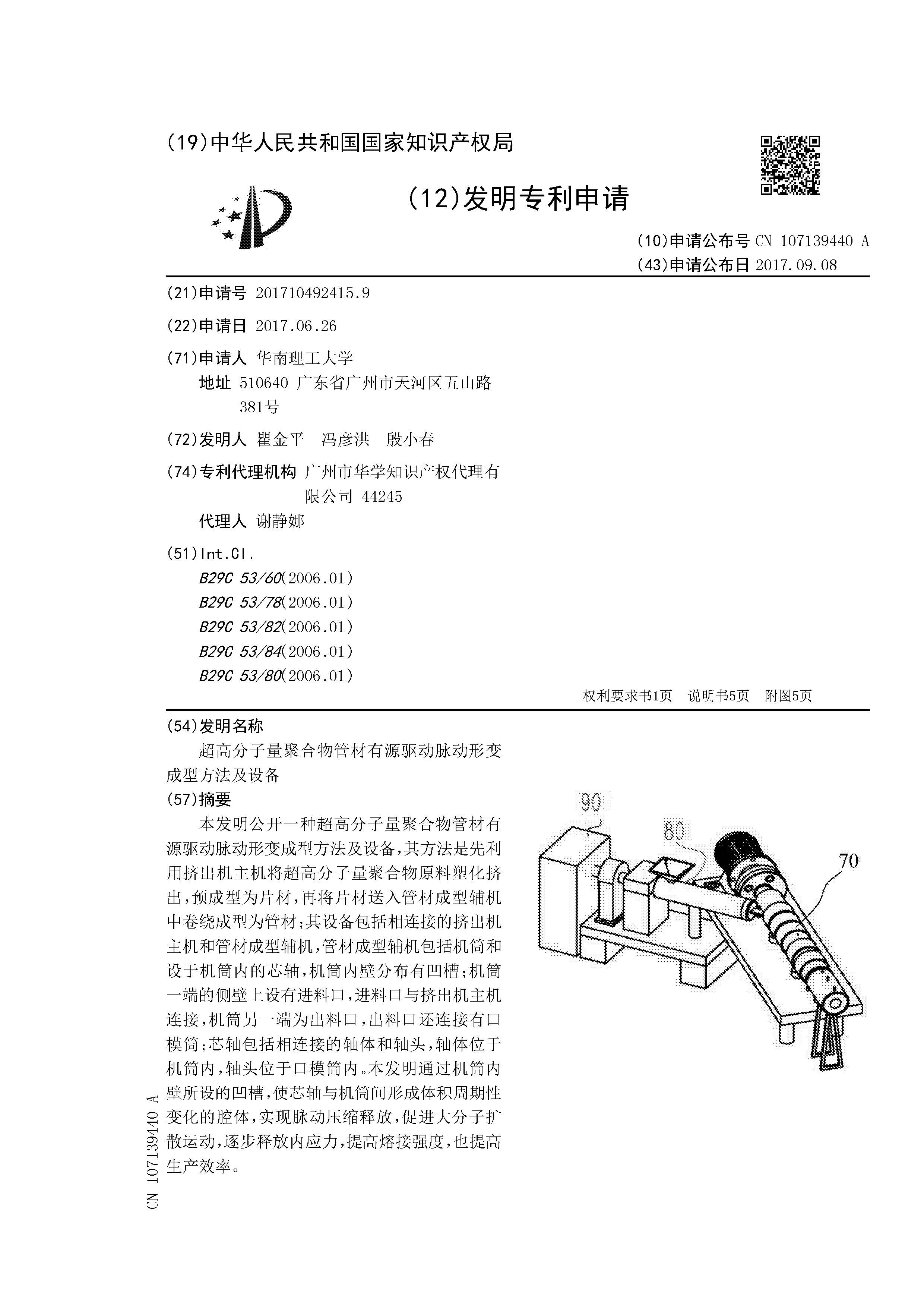

本发明公开一种超高分子量聚合物管材有源驱动脉动形变成型方法及设备,其方法是先利用挤出机主机将超高分子量聚合物原料塑化挤出,预成型为片材,再将片材送入管材成型辅机中卷绕成型为管材;其设备包括相连接的挤出机主机和管材成型辅机,管材成型辅机包括机筒和设于机筒内的芯轴,机筒内壁分布有凹槽;机筒一端的侧壁上设有进料口,进料口与挤出机主机连接,机筒另一端为出料口,出料口还连接有口模筒;芯轴包括相连接的轴体和轴头,轴体位于机筒内,轴头位于口模筒内。本发明通过机筒内壁所设的凹槽,使芯轴与机筒间形成体积周期性变化的腔体,实现脉动压缩释放,促进大分子扩散运动,逐步释放内应力,提高熔接强度,也提高生产效率。

The invention discloses an ultra-high molecular weight polymer pipe active-driving pulse-deformation forming method and device. The method comprises the following steps: first, an ultra-high molecular weight polymer material is subjected to plasticizing extrusion by utilizing an extruder host; next, a sheet is preformed; and then, the sheet is fed into a pipe forming auxiliary machine and wound to form the pipe. The device comprises the extruder host and the pipe forming auxiliary machine, wherein the pipe forming auxiliary machine comprises a machine cylinder and a core shaft arranged in the machine cylinder; grooves are distributed on the inner wall of the machine cylinder; a feeding port is arranged on the side wall of one end of the machine cylinder and connected with the extruder host; a discharging port is arranged at the other end of the machine cylinder and connected with a die cylinder; the core shaft comprises a shaft body and a shaft head which are connected mutually; the shaft body is positioned in the machine cylinder; and the shaft head is positioned in the die cylinder. The method and the device disclosed by the invention have the advantages that through the grooves arranged on the inner wall of the machine cylinder, a cavity of which the volume changes periodically is formed between the core shaft and the machine cylinder, thereby achieving the pulse compression release; the macromolecular diffusion motion is promoted and the internal stress is released step by step; and not only the welding strength but also the production efficiency are improved.